Page 16

32

31

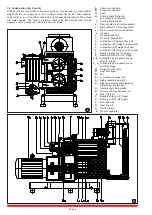

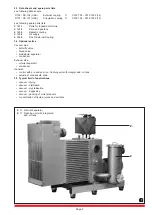

8. Repairs to Gearbox

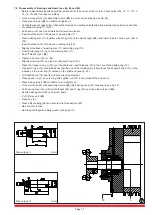

8.1 Removal and Re-assembly of Gearbox (fig. 30 and 31)

• Drain oil (see data sheets D 134 + D 137).

- Fresh oil at (K) / Bearing oil LP at (K

1

) and HP at (K

2

)

- Gearbox oil at (K

3

)

• Remove drive motor (see page 12).

• Remove locking ring (87) on the drive shaft (72).

• Pull coupling (G

3

) from the drive shaft with a puller.

• Take out key (151).

• Remove allen screws in bearing cover (81) and withdraw bearing

cover from drive shaft (72) with sealing (83) (and shaft seal (82)).

• Dis-connect all oil lines from the oil pump (185) (marking

identification).

• Remove oil pump (185) with seal (88).

• Remove oil pump flange (80) with seal (83) (shaft seal (82) is

located in the flange (80)).

• Remove spring shim (79).

• Unscrew all screws in the gear box (70) - including those around

the coupling.

• With the puller (W

7

) loosen the gearbox housing (70) from the

locating pins (108) while turning the screws simultaneous and

remove it.

• Re-assembly in reverse order. Note the following:

- Bearing cover (80) and shaft seal (82) will be carefully pushed

without sleeve along the shaft.

- Bearing cover (81) and

shaft seal (82) will be

mounted with assembly

sleeve type III (W

3

).

• Re-assembly of drive (see

page 12).

• Refill with oil (see data

sheets D 134 + D 137).

- Fresh oil at (H)

- Bearing oil LP at (H

1

) and

HP at (H

2

)

- Gearbox oil at (H

3

)

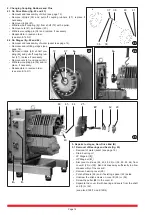

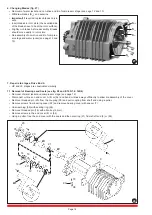

8.2 Changing Gear Wheels and Ball Bearings in Gearbox

Housing (fig. 31 and 32)

• Removal and Re-assembly of gearbox.

• Withdraw both bearings (26) with a puller (W

8

) (do not use the

bearings again).

• Bend back locking tab (77).

• Remove shaft nut (78) with a C spanner (W

9

).

• Remove back locking tab (77).

• Pull off gear wheels (73) and (75).

• Assemble in reverse order.

• Before pressing on bearing (26) their inner ring should be

warmed to 100°C.

W

9

89

108

75

72

73

26

W

8

70

W

7

30

185

80

87

81

G

3

G

3