33

20141167

GB

Start-up, calibration and operation of the burner

6.1

Notes on safety for the first start-up

6.2

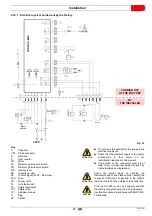

Adjustments prior to ignition

Check the adjustment of the head as shown in page 16.

Check that the air damper has been correctly adjusted.

Slowly open the manual valves situated upstream from the

gas train.

Adjust the air pressure switch to start of the scale.

Purge the air from the gas line.

We recommend using a plastic tube routed outside the

building and to purge air until gas is smelt.

6.2.1

Air damper setting

Do not carry out the first ignition with the air damper lower than

set point 1.

The air damper leaves the factory set for minimum output.

To vary the setting proceed as follows:

loosen the nut 9) (Fig. 11) and act on the screw 8)(Fig. 11).

When burner shuts down the air damper automatically close

still a max. chimney depressure of 0.5 mbar.

6.3

Gas pressure switch

6.4

Air pressure switch

The air pressure switch is set after all other adjustments have

been made. Begin with the switch at the start of the scale.

With the burner function at the required output, turn the knob

slowly in a clockwise direction until burner lockout.

Now turn the knob one notch anti-clockwise and repeat the

burner start-up to check everything is regular.

If the burner locks out again, turn the knob again by half a notch.

6.5

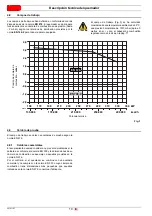

Combustion adjustment

In conformity with Efficiency Directive EN 676, the application of

the burner on the boiler, the adjustment and testing must be

carried out in compliance with the instruction manual of the boiler,

including control of the CO and CO

2

concentration in the flue

gases, their temperature and the average temperature of the

water in the boiler.

It is advisable to set the burner according to the type of gas used

and following the indications in Tab. S.

Tab. S

6

Start-up, calibration and operation of the burner

ATTENTION

The first start-up of the burner must be carried out

by qualified personnel, as indicated in this manual

and in compliance with the standards and

regulations of the laws in force.

ATTENTION

Check the correct working of the adjustment,

command and safety devices.

CAUTION

Before starting up the burner, it is good practice to

adjust the gas train so that ignition takes place in

conditions of maximum safety, i.e. with gas

delivery at the minimum.

ATTENTION

To calibrate the gas pressure switch, refer to the

gas train manual.

ATTENTION

In conformity with the standard, the air pressure

switch must prevent the air pressure falling

below 80% of the adjusted value and the CO in

the flue gases exceeding 1% (10,000 ppm).

To check this, insert a combustion analyser in

the flue, slowly reduce the burner air setting (for

example with a piece of cardboard) and verify

that the burner locks out before the CO value in

the flue gases exceeds 1%.

EN 676

Excess air: max. output

1.2 – min. output

1.3

GAS

Theoretical max CO2

0 % O2

Setting CO2 %

CO

mg/kWh

NOx

mg/kWh

= 1.2

= 1.3

G 20

11.7

9.7

9.0

100

170

G 25

11.5

9.5

8.8

100

170

G 30

14.0

11.6

10.7

100

230

G 31

13.7

11.4

10.5

100

230