36

COMMISSIONING AND MAINtENANCE

9

Carefully check for absence of leakages from the closing

point of the plug.

9

Do not force beyond the stop point to prevent damaging the

shaft and causing leakage as a consequence.

9

Use equipment suitable for the system refrigerant.

9

Use only the system refrigerant.

9

Any gas leaks indoors can generate toxic gases if they come

into contact with naked flames or high temperature bodies,

in case of leaks, please air the rooms thoroughly.

9

Take anti-static precautions in case of weather conditions

where humidity is less than 40%.

9

Avoid using mobile phones.

9

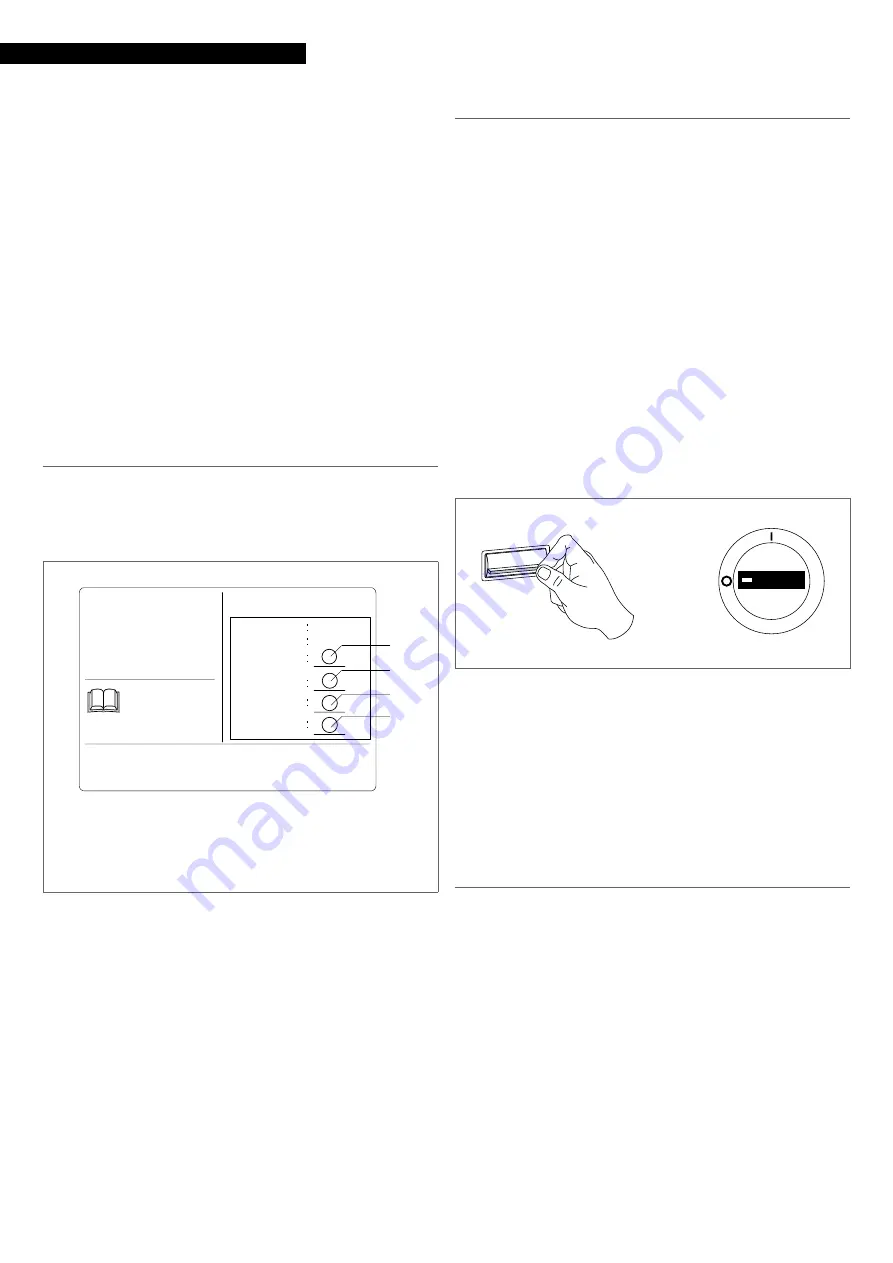

3.2.1

Refrigerant label

In base alla Normativa CE n. 517/2014 su determinati gas floru-

rati ad effetto serra, è obbligatorio indicare la quantità totale

di refrigerante presente sistema installato. Tale informazione è

presente nella targhetta tecnica presente nell'unità esterna.

A

Standard charge

B

Additional charge

C

Total charge

D

Equivalent total weight of CO2

QUESTO APPARECCHIO CONTIENE

GAS AD EFFETTO SERRA COPERTI

DAL PROTOCOLLO DI KYOTO.

INFORMAZIONI SUL REFRIGERANTE

Refrigerante

Carica addizionale

Carica totale

Carica di fabbrica

(vedi etichetta tecnica)

É VIETATO DISPERDERE

IL GAS R32 DIRETTAMENTE

IN ATMOSFERA

Istruzioni per compilare l’Etichetta “F-Gas Label”:

1 - Annotare le quantità sull’etichetta con inchiostro indelebile

2 - Collocare l’adesivo plastico di protezione (consegnato assieme al manuale)

3 - Peso equivalente CO2 del sistema in tonnellate = Carica totale in kg / 1000 x GWP

GW

P

675

R32

A

B

C

D

Peso equivalente CO2

kg

kg

kg

t

To write the tag:

—

note the quantity onto the label with indelible ink

—

place the refrigerant gas label on the outdoor unit

9

This unit contains fluorinated greenhouse gases covered

by the Kyoto protocol. Maintenance and disposal activities

must be carried out exclusively by skilled personnel.

9

Global warming potential of the R32 refrigerant gas: GWP=675

9

If necessary, the refrigerant must be recovered and not di-

spersed into the environment.

0

It is forbidden to disperse the refrigerant into the environ-

ment.

0

3.3

Ordinary maintenance

Routine maintenance is fundamental for keeping the equip-

ment efficient, safe and reliable. It can be performed periodi-

cally by the Technical Support Service, whose staff is technically

qualified and can use genuine spare parts, if necessary.

9

For units installed in a seaside environment, the mainte-

nance intervals shall be halved.

9

Original conditions must be restored after performing the

required maintenance operations.

9

All described operations MUST be carried out under the fol-

lowing conditions:

—

cold device

—

device NOT supplied with electric power

—

suitable personal protection equipment

0

Do not open the access covers and carry out technical or

cleaning activities before disconnecting the unit from the

power grid by positioning the system's main switch in the

"OFF" position.

ON

OFF

—

position the system's main switch in the "OFF" position.

9

Wait 10 minutes before touching the device electric compo-

nents.

9

Check with a tester that the voltage between the power

supply connectors of the main electronic board is lower

than 10 Vdc.

9

Yearly operations

The annual maintenance plan includes the following checks:

—

power supply voltage

—

electric connection tightening

—

status of cooling and hydraulic joint

—

finned coil cleaning

—

electric absorption

—

fan grille cleaning

—

Cleaning the heat exchanger fins

The thermal exchange bank must be cleaned with compressed

air.

Cleaning must be carried out at least once a year, according to

the location of the unit, as dirt accumulating between the fins

narrows the passage section and reduces the exchange capa-

bility.

—

check the alignment of the bank's aluminium fins and, if

necessary, straighten them with the appropriate comb

Summary of Contents for 20153499

Page 29: ...29 Installation MODEL 1100 M ...

Page 31: ...31 Installation MODEL 1125 T 1140 T ...

Page 42: ......

Page 43: ......