OPERATION

76

1

Quality Start Mode— Regaining The

Image Density When The Ink On The Drum

Dries

If the machine is not used for a long

period of time or you change the color

drum unit, the ink on the drum might

dry causing print quality to deterio-

rate. To solve this problem, you can

have the machine carry out a few idle

spins of the drum before a print run.

This will restore image quality and

save you having to make a repeat

print run.

You can use this feature in two ways:

❖

❖

❖

❖

Manual Quality Start

Choose Quality Start for the next

print run manually using the

{

Quality Start

}

key.

❖

❖

❖

❖

Auto Quality Start

Have the machine check automati-

cally how long ago the machine

was used before each print run. If

the machine has not been used for

a long time, Quality Start will be

used for the print job. By default,

Auto Quality Start mode is on. You

can turn it off with the user tools.

See “Setting Q. start” in

.

Note

❒

You can change the number of

spins in Manual Quality Start

mode with the user tools. See

“Idling for Q.start” in

❒

You can change the number of

spins after the fixed time period

has passed in Auto Quality Start

mode with the user tools. See “No.

of Q.start” in

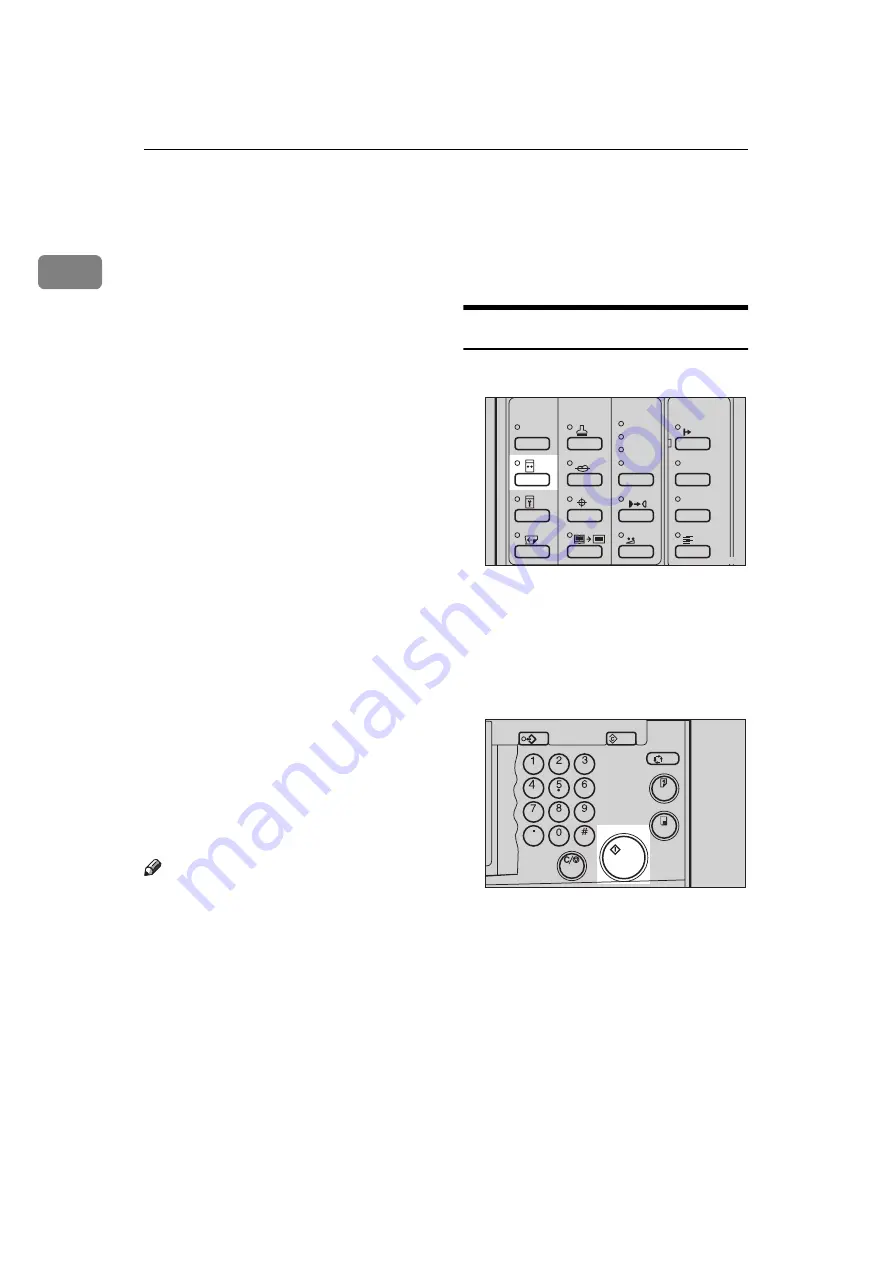

Using Quality Start Manually

A

Press the

{{{{

Quality Start

}}}}

key.

B

Set your original on the exposure

glass (contact glass) or in the op-

tional document feeder.

C

Press the

{{{{

Start

}}}}

key.

The drum unit idles.

D

Make your prints.

Stamp

Make-Up

Overlay

Edge Erase

Skip Feed

Economy Mode

Tint

Darker 2

Darker 1

Normal

On Line

Job Separator

Lighter

Image Density

TPES210N

Program

Clear Modes

Auto Cycle

Proof

Enter

Start

Clear/Stop

TPES050N