CIP Training

Plockmatic SquareBack Trimmer

Setting Up a Job

Square Back

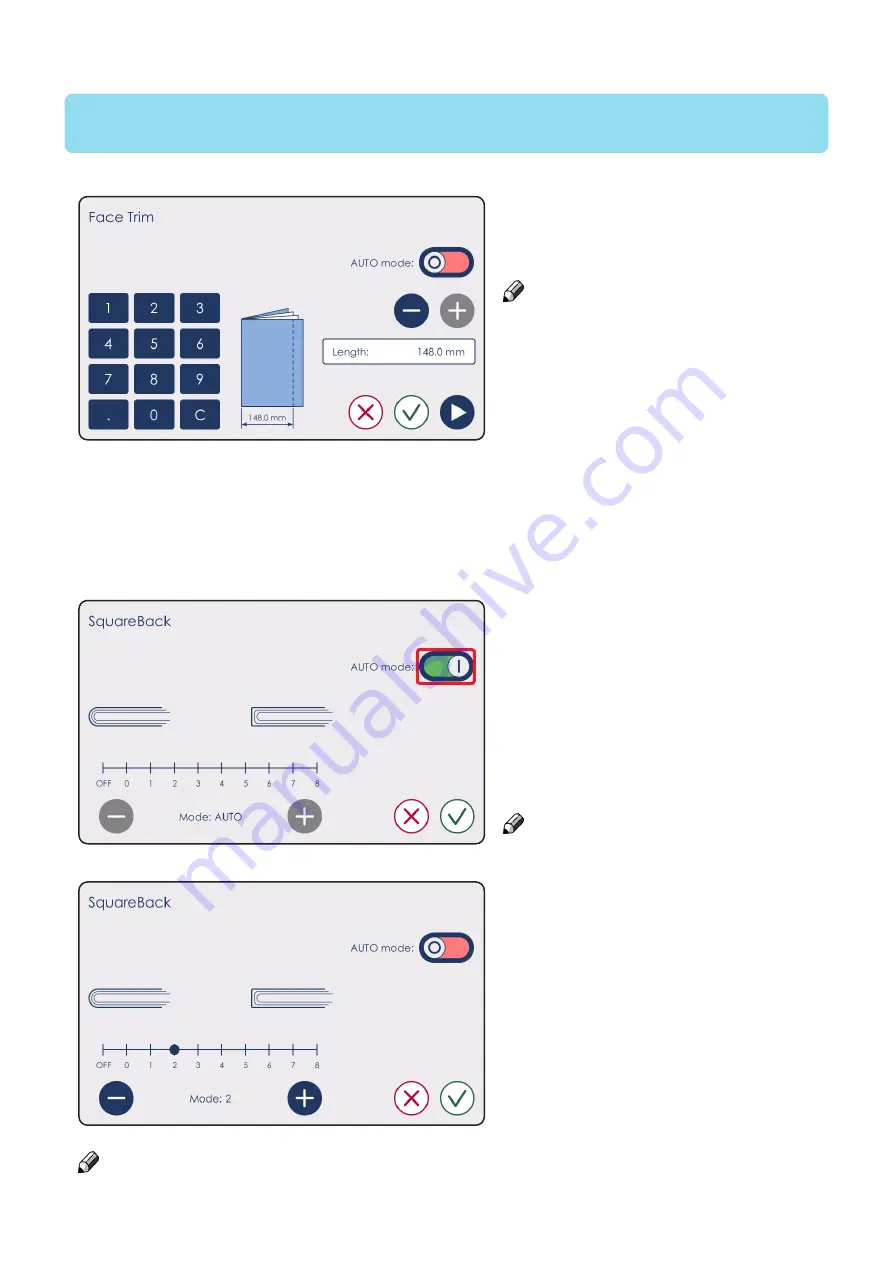

The operator has the option of

sharpening or softening the square

edges of the finished booklet based

on application or preference.

The Auto mode is on by default but, if

the Square Back is not satisfactory, the

user can adjust it manually by tapping on

the green switch, which will turn the

Auto mode off.

NOTE:

The printer’s settings override the

SquareBack Trimmer settings,

therefore, if this function is turned

off on the printer, it will be turned off

automatically on the SBT.

When turned on on the printer, the SBT

will apply auto settings again.

T

o adjust the amount of Square Back

pressure, press [+] for sharper edges

and [-] for softer edges.

Push the green check mark to confirm

the changes or the red cross to discard

them and to go back to the main menu.

To adjust the amount of face trim, press

[+] or [-] or enter the desired length of

the booklet using the numeric keypad.

Square Back

NOTE:

If the values chosen are out of the paper

bounds, the lengths will automatically

be adjusted to the limit values.

Push the green check mark to confirm the changes or the red cross to discard them and to go

back to the main menu. Pushing the blue play button will bring the user to the next setting:

“Square Back”.

NOTE:

If the Square Back does not give satisfactory results, it might need to be Fine Adjusted. To do

so, see “Square Back Fine Adjustment” under section 5 of this manual.