ERROR

MESSAGES

SM 4-35 B273

Trouble-

shooting

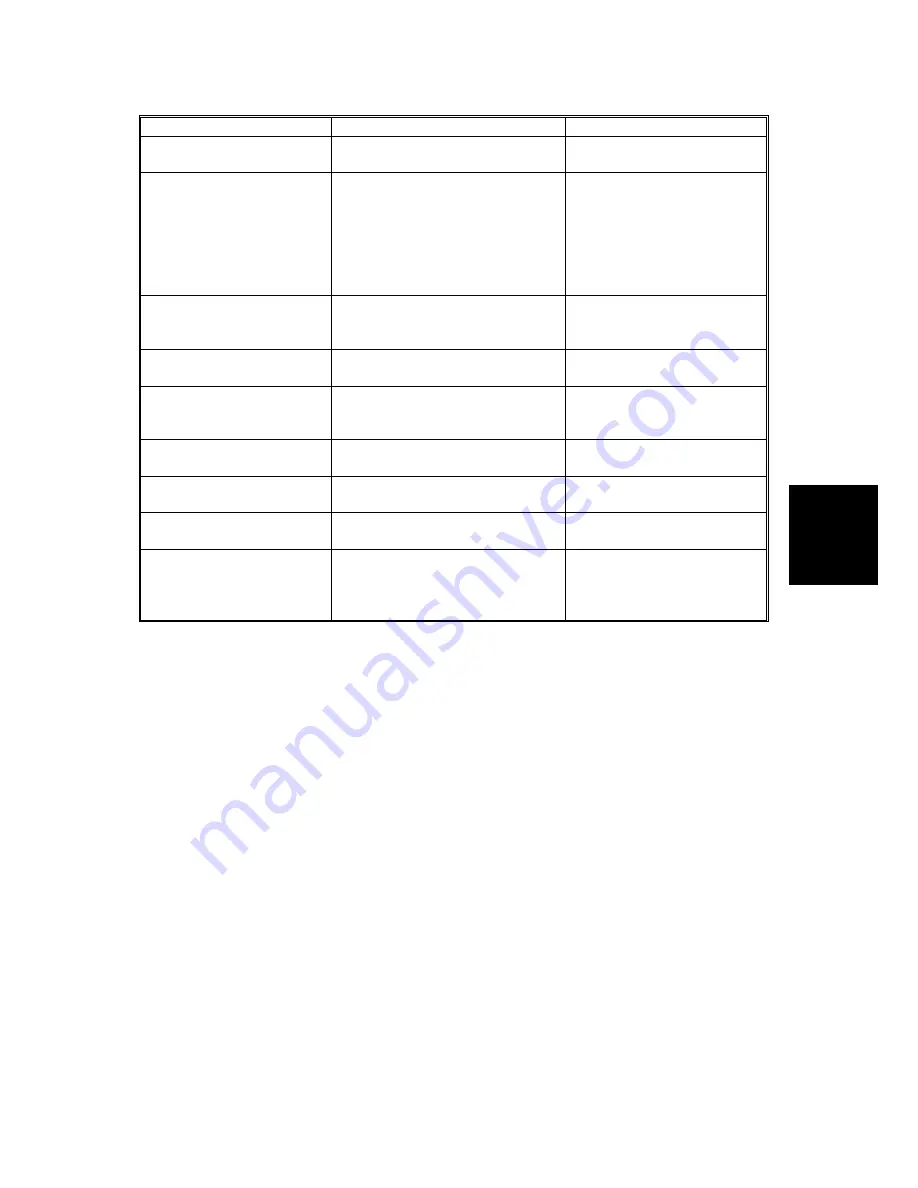

Error Description Solution

Priority fax function full

The priority fax job queue is full.

Cancel unnecessary priority

fax jobs.

Incompatible

The remote machine does not

have the requested feature, such

as sending a color fax.

This message can also show if

the remote machine does not

have enough memory to

complete the job.

Reconfirm the features of

the remote machine.

Jam1 or No cartridge

Paper is jammed in the paper

exit area, or the toner cartridge is

not installed.

Clear the jam.

Install the toner cartridge.

Line busy

The receiving machine does not

answer, or the line is busy.

Try again later.

Load document

An attempt has been made to set

up a copy/fax job, but no

document is loaded in the ADF.

Load the document in the

ADF and try again.

Scanner locked

The scanner module is locked.

Unlock the scanner and

press Stop/Clear.

Stop pressed

The Stop/Copy button was

pressed during a copy/fax job.

Try again.

Toner empty replace toner The toner cartridge has run out

and the machine stops printing.

Replace the toner cartridge.

Retry redial

The machine is waiting for a

specified timer interval to dial a

previously busy station again.

Press <Enter> to

immediately redial, or press

Stop/Clear to cancel the

redial operation.

Summary of Contents for AC205

Page 1: ...B273 SERVICE MANUAL 002544MIU ...

Page 2: ......

Page 3: ...B273 SERVICE MANUAL ...

Page 4: ......

Page 5: ...B273 SERVICE MANUAL 002544MIU ...

Page 6: ......

Page 8: ......

Page 10: ......

Page 12: ......

Page 24: ......

Page 26: ......

Page 27: ...INSTALLATION ...

Page 28: ......

Page 30: ......

Page 31: ...PREVENTIVE MAINTENANCE ...

Page 32: ......

Page 34: ......

Page 35: ...REPLACEMENT AND ADJUSTMENT ...

Page 36: ......

Page 85: ...TROUBLESHOOTING ...

Page 86: ......

Page 135: ...SERVICE PROGRAM MODE ...

Page 136: ......

Page 152: ......

Page 153: ...DETAILED DESCRIPTIONS ...

Page 154: ......

Page 175: ...SPECIFICATIONS ...

Page 176: ......

Page 184: ......

Page 185: ...APPENDIX ...

Page 186: ......

Page 187: ...BLOCK DIAGRAM SM 8 1 B273 Appendix APPENDIX BLOCK DIAGRAM B273X01 WMF ...

Page 188: ...CONNECTION DIAGRAM B273 8 2 SM CONNECTION DIAGRAM B273X02 WMF ...