Install Cabling in Conduit

13

The best grounding system for the scale is the same grounding system used for the incoming AC power system.

The 120 VAC power source used to power the indicator is connected to an existing earth ground rod system at the

scale house or other building where the indicator is located. This consist of a double ground rod system of two 5/

8" x 8' copper rods driven 8' deep at the service entrance where the local utility company brings their lines into

the building. The local utility company can test the resistance of the existing ground rods with a clamp-on

megohmeter to measure resistance. A reading of 3¾ or less is acceptable as a ground. If the test determines that

the grounding system is inadequate, the utility company can suggest methods to improve the system. It is crucial

that the scale owner authorize and make the recommended improvements to assure an adequate electrical

ground. Do not connect the scale to the AC power supply until the grounding system is adequate.

Each load cell grounding strap is securely fastened to the top and bottom plates of each load cell mount. The

grounding strap is designed to channel power surges on the deck around—rather than through—the load cell to

ground. All ground connections must be properly torqued and rechecked at regular service intervals. After

connecting to bare metal apply a thick coating of anti-oxidant grease on all ground connections to prevent

corrosion.

A separate grounding system conductor must extend uninterrupted from the main service panel ground to the

scale to protect load cells and scale wiring from lightning and other transient damage. As a minimum

requirement for ground wire installation, the conductor must be at least a 10-gauge unsheathed copper wire. Run

the bare ground wire conductor intact from the AC power ground rod to the scale in a separate trench.

Bring the

wire up from the trench near the junction box and attach it to the ground lug of the junction box. Use a short piece

of 10-gauge wire to ground the scale frame by running a ground wire from the junction box ground lug to a

junction box mounting bolt on the scale frame.

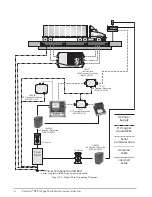

5.7 Install Transient Protection

An two-year lightning protection package comes standard on all SURVIVOR

®

PT Pit-Type

truck scales. This

package is designed to protect the AC and DC portions of the system. The package includes:

•

A DC transient protection board mounted within the junction box. This DC transient protector can

accommodate up to eight load cells and will help protect serial communication lines. Scales with more

than eight load cells require a DC transient protection board in each junction box.

•

A self-contained DC transient protection unit in the homerun cable at the indicator.

•

A 10-gauge bare ground conductor cable. This conductor cable, to be buried underground, runs from the

scale frame to the junction box DC transient board, to the indicator DC transient board, and finally to the

AC power ground lug.

•

A 120 VAC uninterruptable power supply/surge protector in the AC line before the indicator.

NOTE:

Transient protection for additional peripheral devices (except some boards) is not included in the standard transient

protection package. Call the Rice Lake Weighing

S

ystems

S

ales Department at (715) 234-9171 for additional transient protection

for these devices.