Installation

1

Introduction

This manual is intended for use by technicians

responsible for installing and servicing the

PT

Pit-Type

series truck scale. You will find that the

PT

Pit-Type

truck scale has been designed so that your

on-site installation time is reduced as much as

possible. A well-organized, experienced installation

crew should be able to install a typical 70’x 11’ truck

scale in one day.

NOTE:

This booklet covers the

PT Pit-Type

truck scale

installations. Use these instructions as general installation

guidelines unless the engineering drawings furnished with

your scale differ from the instruction in this booklet.

Engineering drawings furnished with your scale always take

priority over these general installation guidelines.

Refer to the engineering drawings furnished with the scale for

all component numbering sequences.

A u t h o r i z e d d i s t r i b u t o r s a n d t h e i r

employees can view or download this

manual from the Rice Lake Weighing

S y s t e m s d i s t r i b u t o r s i t e a t

www.ricelake.com

.

1.0

Installation

The modular sections of the SURVIVOR

®

PT Pit-Type

truck scale are shipped pre-assembled and ready to be

placed into position on temporary setting blocks using a crane capable of handling 10,000 lbs. The individual

modules are bolted together and the deck is leveled in final position flush with the top of the pit. Mounts are

shipped pre-assembled with load cells, adapters, and flexible conduit sections attached. Mounts are installed to

the level of the deck, then anchored and grouted to the foundation. Cabling is run in conduit and electronic

equipment connected to finish the installation.

The general assembly order is summarized below:

1. Set deck modules into position on setting blocks and bolt deck modules together.

2. Install outriggers and deck channel coping.

3. Place deck into final position even with top of pit.

4. Assemble mounts with load cells to the deck unit; remove setting blocks.

5. Install mount anchor bolts and grout beneath mount plates.

6. Install corrugated sheet metal, rebar and pour concrete.

7. Run cabling through conduit; make electrical connections.

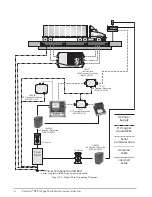

8. Connect indicator and peripheral devices.

9. Calibrate scale.

1.1

Foundation Slab Cure Period

Standard concrete reaches full strength after a 28-day cure. Note that the concrete foundation must cure in a

moist state for at least seven days (three days for high-early concrete). At seven days, standard concrete is

approximately 75% of its maximum strength and can handle moderate loads. Loading of a slab before it reaches

75% of maximum strength may damage the foundation.

1.2

Assembly Time Estimates

When scheduling installation for a typical three-section, 70' truck scale, plan for a two-hour minimum crane

rental to position the sections.

A two-man crew, aided by a crane operator, can unload modules from the truck, place them into position and bolt

them together in one to two hours. Mount and load cell installation requires approximately two hours. All

electrical wiring and final connections can normally be completed the same day.

Note: These estimated times may vary.