Introduction

©

Rice Lake Weighing Systems

●

All Rights Reserved

1

1.0

Introduction

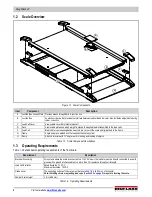

This manual is intended for use by service technicians responsible for installing and servicing RoughDeck

®

LP floor scales. The

RoughDeck LP floor scales are fully electronic, low-profile load receivers with a 2000 lb (907.20 kg) capacity.

Manuals and additional resources are available from Rice Lake Weighing Systems at

Warranty information can be found on the website at

1.1 Safety

Safety Definitions:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury. Includes

hazards that are exposed when guards are removed.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in serious injury or death. Includes

hazards that are exposed when guards are removed.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, could result in minor or moderate injury.

IMPORTANT: Indicates information about procedures that, if not observed, could result in damage to equipment or

corruption to and loss of data.

General Safety

Do not operate or work on this equipment unless this manual has been read and all instructions are understood.

Failure to follow the instructions or heed the warnings could result in injury or death. Contact any Rice Lake

Weighing Systems dealer for replacement manuals.

WARNING

Failure to heed could result in serious injury or death.

Before opening the unit, ensure the power cord is disconnected from the outlet.

Do not allow minors (children) or inexperienced persons to operate this unit.

Do not operate without all shields and guards in place.

Do not jump on the scale.

Do not use for purposes other then weight taking.

Do not place fingers into slots or possible pinch points.

Do not use any load bearing component that is worn beyond 5% of the original dimension.

Do not use this product if any components are cracked.

Do not exceed the rated load limit of the unit.

Do not make alterations or modifications to the unit.

Do not remove or obscure warning labels.

Do not use near water.

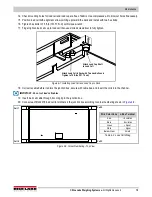

Do not lift scale without ensuring shoulder support screws (

) are in installed in each corner (under load cell

corner covers).