29

Table L: Category I Vertical Venting

* Vent lengths are based on a lateral length of 2 ft. Refer to the latest edition of the NFGC for further details.

When vertical height exceeds 25 ft, consult factory prior to installation.

** Subtract 10 ft per elbow. Max. 3 elbows.

Maximum combustion air duct length terminated at 100 equivalent ft.

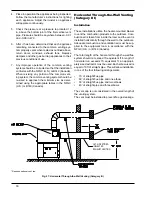

Manifolds that connect more than one heater to a com-

mon chimney must be sized to handle the combined

load. Consult available guides for proper sizing of the

manifold and the chimney. At no time should the area

of the common vent be less than the area of the largest

heater exhaust outlet.

Common venting systems may be too large once an

existing unit is removed. At the time of removal of an

existing appliance,

the following steps must be fol-

lowed

with each appliance remaining connected to the

common venting system placed in operation, while the

other appliances remaining connected to the common

venting system are not in operation.

A

WARNING:

Vent connectors serving applianc-

es vented by natural draft shall not be connected

into any portion of mechanical draft systems op-

erating under a positive pressure.

1. Seal any unused opening in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch and verify there is no block-

age, restriction, leakage, corrosion or other unsafe

condition.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the com-

mon venting system are located and other spaces

of the building. Turn on clothes dryers and any ap-

pliance not connected to the common vent system.

Turn on any exhaust fans, such as range hoods

and bathroom exhausts, at maximum speed. Do

not operate summer exhaust fan. Close fireplace

dampers.

Model

No.

Certified

Venting

Material

Vent

Size

Vertical Venting

Height*

Combustion

Air

Intake Pipe

Material

Air Inlet Max. Length**

Min.

Max.

6”

8”

10”

12”

399B

Category I

(Type B

Equivalent)

6”

5’

25’

Galvanized

Steel,

PVC, ABS,

CPVC

100’

499B

75’

100’

649B

8”

40’

749B

899B

989B

10”

75’

100’

1259B

12”

1529B

1799B

14”

40’

75’

1999B

2069B

2339B

16”

A

CAUTION:

Vent connectors for natural draft

venting systems must be Type B or better.

Summary of Contents for Raypak Delta Limited 399B

Page 39: ...39 Wiring Diagram Models 399B 1259B...

Page 40: ...40 Wiring Diagram Models 1529B 2339B...

Page 51: ...51 DIAGNOSTIC DETAIL 12 J 7 J 6 J 5 J 3 0 2 0 16 S 1 F 2 F 3 F 4 F BLOWER DETAIL...

Page 53: ...53 13 J 8 J 10 J 11 J 4 J 2 J 3 J 6 C 14 J 9 J 1 J CONTROL BOX DETAILS...

Page 57: ...57 ILLUSTRATED PARTS LIST MODELS 989B 2339B 10 J 3 O 5 O...

Page 58: ...58 12 H 6 H 7 H 8 H 2 H 9 H 3 H 5 H 1 H 4 H 1 P HEAT EXCHANGER DETAILS BURNER ASSEMBLY DETAILS...

Page 59: ...59 CONTROL BOX DETAILS 9 J 8 J 23 S 13 J 10 J 3 O 10 J 3 O 5 O FRONT SWITCH DETAILS...

Page 66: ...66...

Page 67: ...67 Raypak Inc 2151 Eastman Avenue Oxnard CA 93030 805 278 5300 Litho in U S A NOTES...