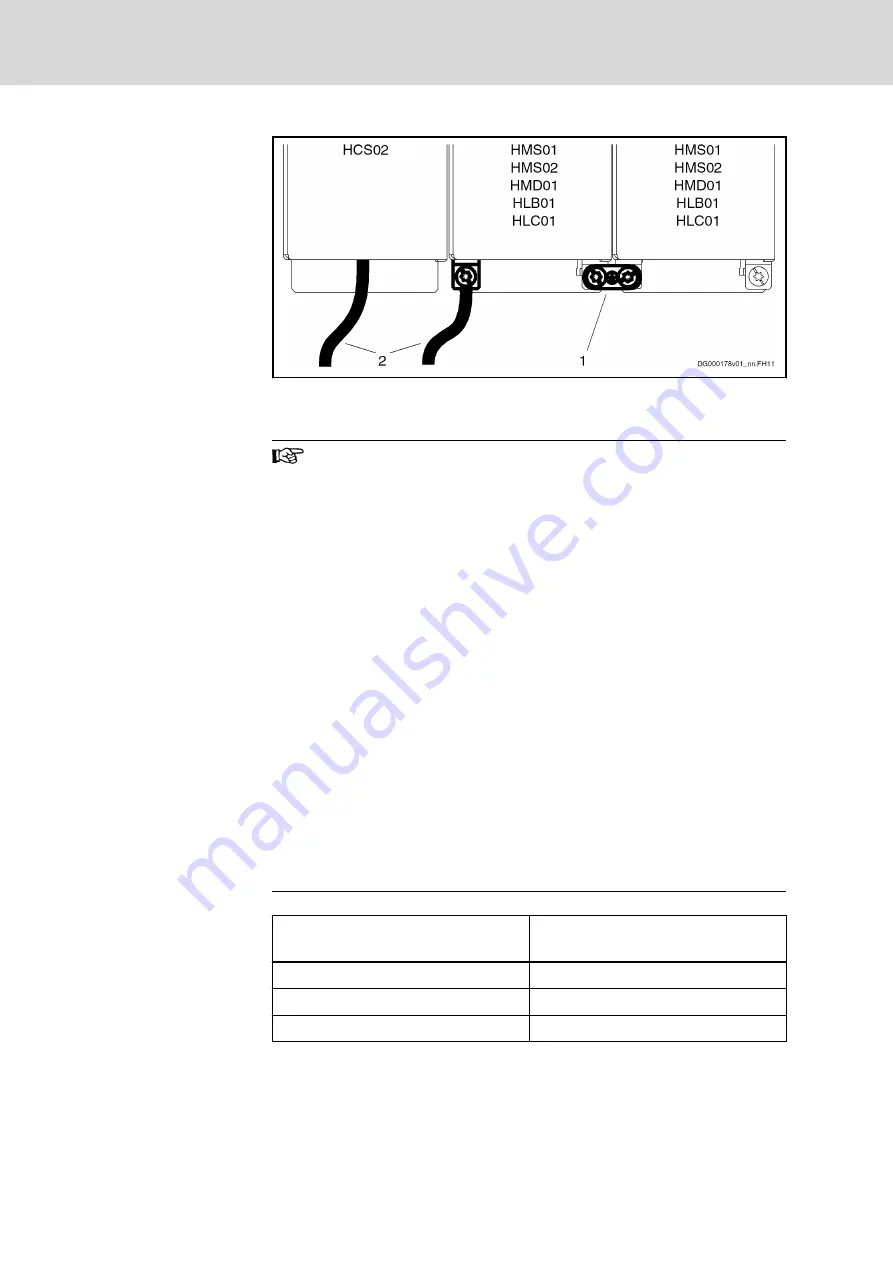

1

Joint bar

2

Connection to equipment grounding system

Fig.13-5:

Equipment Grounding Conductor Connection for Supply via HCS02

Equipment grounding conductor: Material and cross section

For the equipment grounding conductor, use the same metal (e.g.

copper) as for the outer conductors.

For the connections from the equipment grounding conductor

connection of the device to the equipment grounding conductor

system in the control cabinet, make sure the cross sections of the

lines are sufficient.

Cross sections of the equipment grounding connections:

●

For HCS03.1E drive controllers, HMV01 and HMV02 supply

units at least 10 mm

2

(AWG 8), but not smaller than the

cross sections of the outer conductors of the mains supply

feeder

●

For HCS02.1E drive controllers, at least 4 mm

2

(AWG 10),

but not smaller than the cross sections of the outer conduc‐

tors of the mains supply feeder

Additionally, mount the housing of HCS02.1E to a bare met‐

al mounting plate. Connect the mounting plate, too, with at

least the same cross section to the equipment grounding

conductor system in the control cabinet.

For outer conductors with a cross section greater than 16 mm²,

you can reduce the cross section of the equipment grounding

connection according to the table "Equipment Grounding Conduc‐

tor Cross Section".

Cross-sectional area A of outer conduc‐

tors

Minimum cross-sectional area A

PE

of

equipment grounding connection

A ≤ 16 mm²

A

16 mm² < A ≤ 35 mm²

16

35 mm² < A

A / 2

Tab.13-2:

Equipment Grounding Conductor Cross Section

13.1.5

Connection to Mains Choke and Mains Filter

Order of the connections to the supply mains:

Bosch Rexroth AG

DOK-INDRV*-SYSTEM*****-PR06-EN-P

Rexroth IndraDrive Drive Systems with HMV01/02 HMS01/02, HMD01, HCS02/03

226/309

Connections of the Components in the Drive System