Falk

®

Rigid Moment Couplings

•

Installation & Maintenance

Type MCF

•

Size 1135

(Page 3 of 4)

Rexnord

CP3-006

5555 S. Moorland Rd., New Berlin, WI 53151-7953

February 2015

Telephone: 262-796-4060 Fax: 262-796-4064 www.rexnord.com

NEW

Coupling Disconnection

WARNING

:

Do not disconnect torque arm or tie rod until

the low-speed coupling is completely disconnected.

1. With suitable equipment, remove the weight of the

drive assembly from the coupling and driven shafts. It

is necessary to make fine adjustments of position at

each of the bedplate lugs. The lifting slings should have

appropriate provisions for adjustment.

2. Lift the drive by the lifting lugs in the bedplate or wrap

slings around the assembly when a bedplate is not

used. Balance loads so drive is level and will not swing

down when the coupling is disconnected.

3. Loosen flange fasteners in sequence until all fasteners

have at least a 0.125” (3.175 mm) clearance under

the fastener heads. Remove all but one fastener near

the top of the flange. Separate the two flanges using

four 1/2–13UNC fasteners (not supplied with coupling)

inserted in the four jackscrew holes in the male register

flange. Continue backing off the last flange fastener as

the flanges are separated. When completely separated,

adjust the weight of the drive assembly until the weight

is off the last fastener. Carefully remove the last fastener.

4. Adjust the drive assembly position until all the weight of

the assembly is balanced. When the tie rod is no longer

bearing any of the weight, disconnect the tie rod. Slowly

lower the assembly to the ground.

Hub Removal

1. Type 2 Hubs

a. Thoroughly clean hubs of grease and solvents to

avoid combustion when heat is applied.

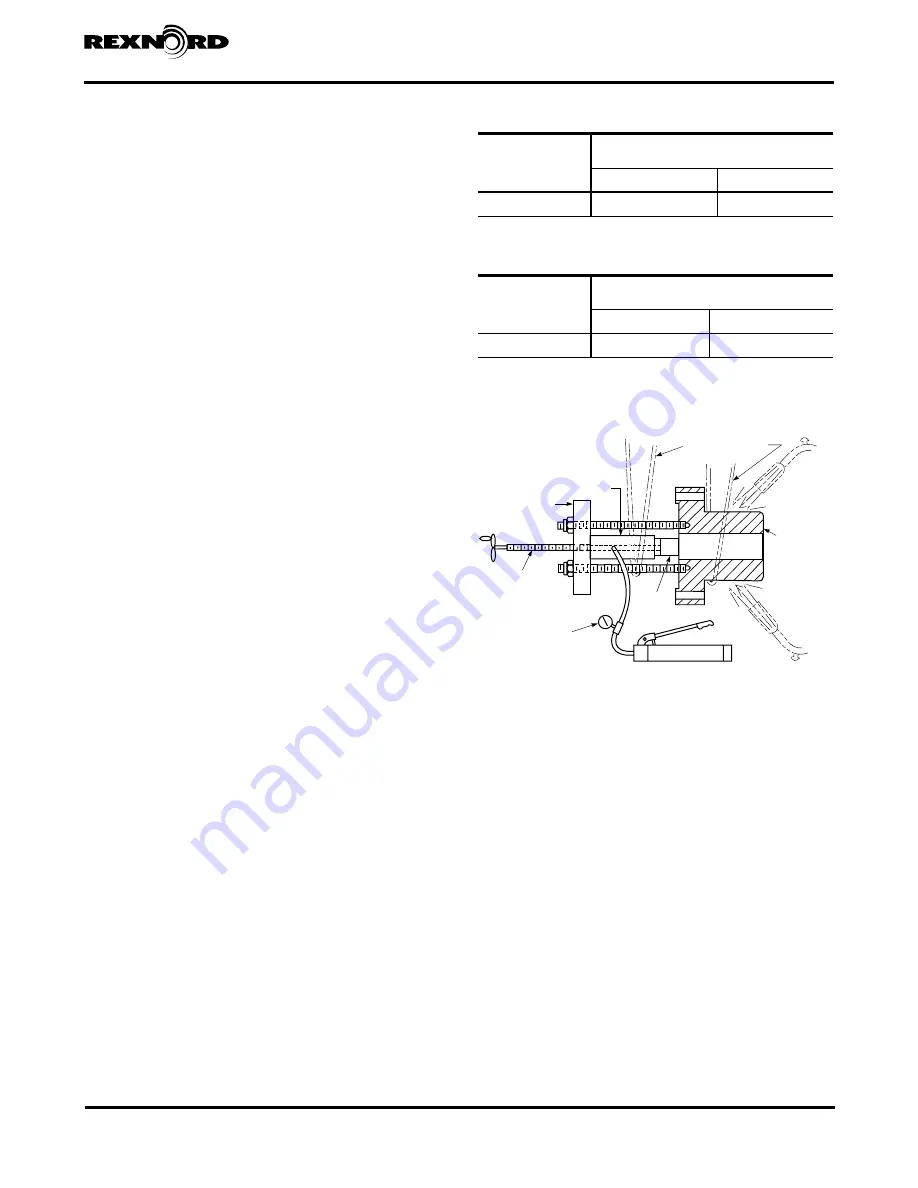

b. Assemble puller as shown in Figure 6. Check to

make sure puller has enough stroke to pull the hub

off. Be sure to adequately support both the hub and

puller assembly using metal cable slings. Reference

Table 3 for the hub puller bolt hole mounting pattern.

c. Heat the hub evenly with a rosebud torch to

approximately 400° to 500°F (204° to 260°C) while

applying pressure to the puller. The temperature may

be measured with a heat-sensitive crayon. Apply

puller pressure until the hub clears the shaft.

2. Type 6 Hubs

a. Mount a hydraulic hub puller (see Figure 7) on the

end of the hub with a pressure rod against the shaft

end. Reference Table 3 for the hub puller bolt hole

mounting pattern. The puller must have an axial

travel equal to or greater than the hub-to-shaft bore

length. Be sure to adequately support both the hub

and puller assembly using metal cable slings.

b. Mount the hydraulic expansion fittings to the hub

and high-pressure hydraulic pump. Pressurize the

hub-to-shaft interface until oil is oozing out between

bore and shaft, or to the removal pressure called

out in Table 4. Apply axial removal force at the same

time as pressurizing the hub. Shut off pressure (item

8 of Figure 7) prior to the groove being exposed

beyond the shaft end.

Table 4 — Type 6 Hub Removal Pressure

COUPLING

SIZE

Maximum Recommended Pressure At Hub Bore

When Dismounting Hub

(MPa)

(psi)

1135 MCF

138 - 152

20,000 - 22,000

Table 3 — Type 2 & Type 6 Hub Puller Bolt

COUPLING

SIZE

Flange Face Puller Bolt Holes

UNC Tap (2 x Dia Deep)

BC - Inch (mm)

UNC Tap (4 @ 180°)

1135 MCF

25.00 (635)

2.000 - 4.5UNC

METAL CABLE SLINGS

TO SUPPORT HUB

AND PULLER

TORCH

COUPLING

HUB

TORCH

SHAFT

BAR

STOCK

HAND PUMP OR

HYDRAULIC PUMP

GAUGE

WITH OR

WITHOUT

ADJUSTING

SCREW

ALLOR STEEL

PLATE

HYDRAULIC

CYLINDER

Figure 6 — BASIC TYPE 2 HUB REMOVAL EQUIPMENT