Installation & Maintenance

•

Falk Rigid Moment Couplings

(Page 2 of 4)

Type MCF

•

Size 1135

CP3-006

Rexnord

February 2015

5555 S. Moorland Rd., New Berlin, WI 53151-7953

NEW

Telephone: 262-796-4060 Fax: 262-796-4064 www.rexnord.com

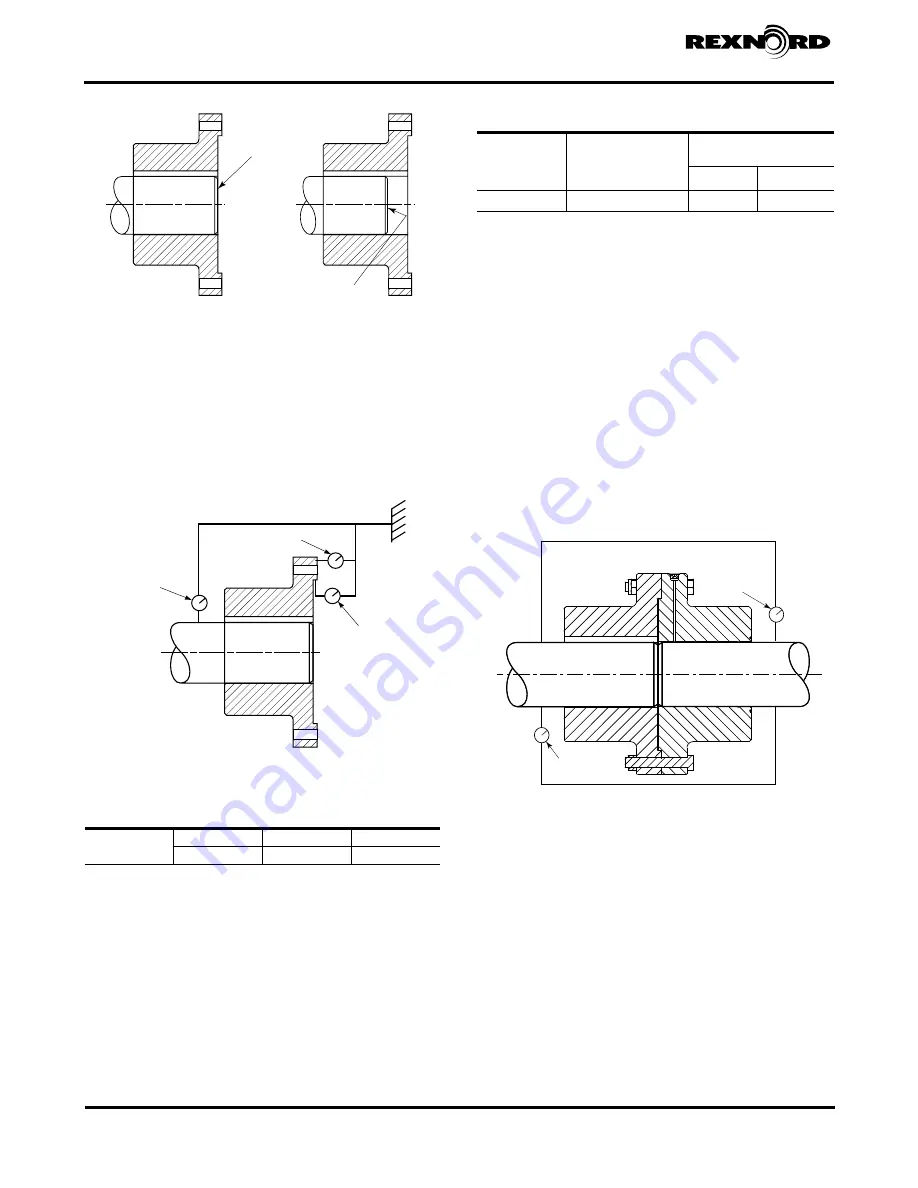

SHAFT END

FLUSH WITH

FACE OF HUB

SHAFT NOT FLUSH

WITH END OF HUB

CORRECT

INCORRECT

c. Check that the hub is correctly positioned on the

shaft, then using dial indicators, check hub runout

as illustrated in Figure 4. Checking the hub runout

ensures correctness of hub mounting and will reduce

drive movement. Make sure runout values do not

exceed limits listed in Table 1. If runout is excessive,

remove hub following the removal instructions, and

carefuly remount the hub to the shaft.

INDICATOR #3

INDICATOR #2

INDICATOR #1

Figure 3

Figure 4

7. With suitable lifting equipment, move the drive/motor

assembly into position, approximately parallel and in

line with the driven shaft using hub flanges as a guide.

Align fastener holes, and install and hand tighten one

flange fastener. Align hub registers and flange fastener

holes. Install all flange bolts finger tight.

8. Use a precision torque wrench and equally tighten all

opposing fasteners while allowing the drive assembly to

move as required to draw the flanges together (flexible

support). Continue tightening until flanges are mated

and all flange fasteners are torqued to values specified

in Table 2.

Table 2 — Flange Fastener Tightening

COUPLING

SIZE

Flange Fastener Size

Grade 8

(Inch)

Flange Fastener Tightening

Torque Tolerance 5%

(Nm)

(lb-ft)

1135 MCF

2.500 - 4 UNC x 11.00

12745

9400

9. Fasten the torque arm to the bed frame per gear drive

instructions and remove the lifting equipment. Rexnord

recommends that a loose, unrestraining safety sling

be attached to the bedplate and support structure to

support the drive in case of an emergency.

10. Using dial indicators per Figure 5, measure assembly

runout on driving and driven shafts. Runout values

should be within 0.005” (0.127 mm) TIR (total indicator

reading) to minimize drive movement. See Table 1.

11. Run the drive for a short period of time, and then

shut off and lockout motor. Recheck all fasteners for

specified torque.

12. The coupling installation is now complete.

WARNING

: Install the warning nameplate supplied

with the coupling on the coupling guard or on some

other support structure near the coupling.

DIAL

INDICATOR

DIAL

INDICATOR

REVERSE DIAL INDICATOR METHOD

Figure 5

Table 1 — Maximum Runouts (TIR) for Dial

Indicators – Inch (mm)

All

Sizes

#1

#2

#3

.001 (0.025)

.003 (0.076)

.003 (0.076)