AN1899 Rev 0.00

Page 4 of 24

January 8, 2014

HIP2103-4DEMO1Z

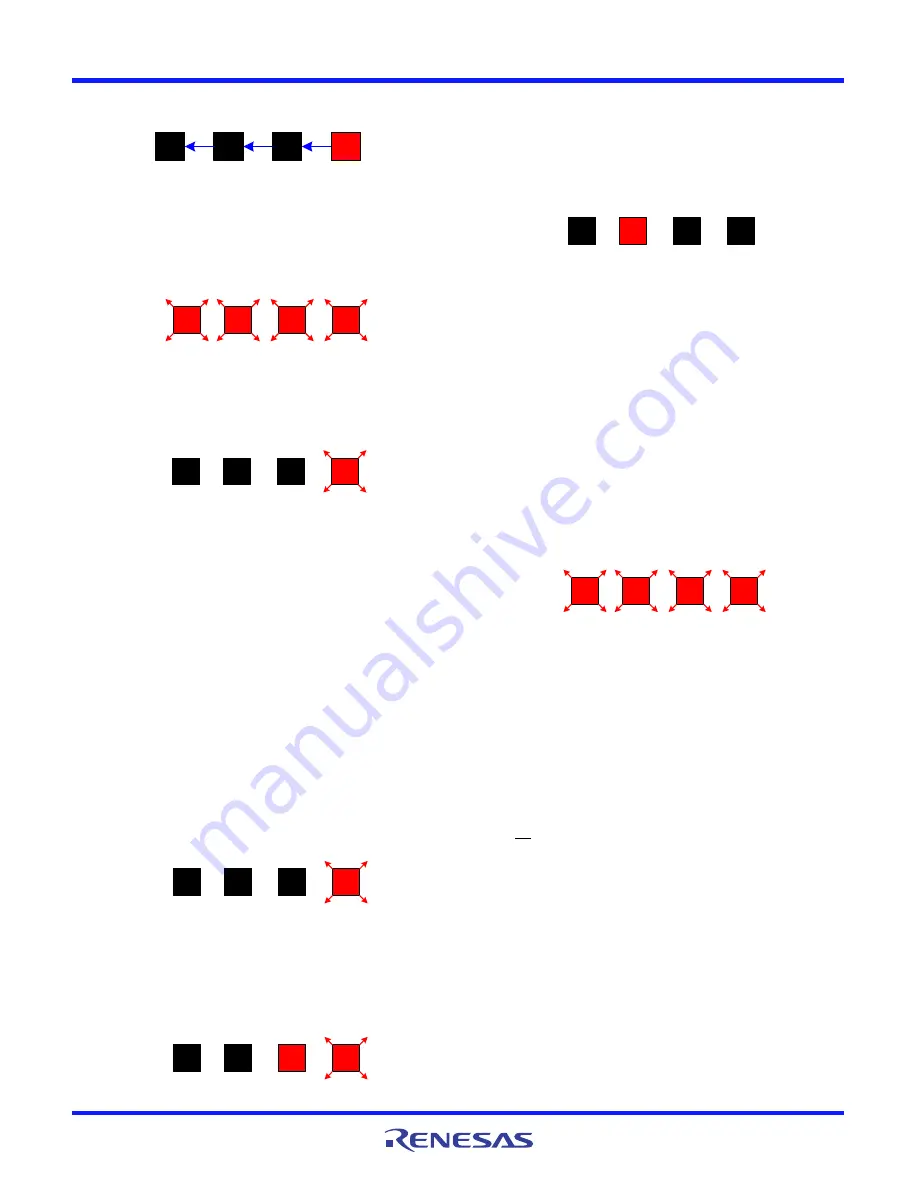

9. Turn on the lab supply. Set SW1 (toggle switch) on. Observe

that the four LEDs turn on and off, one after another.

This initial flash of the LEDs indicates that power has been

applied. After the initial flash, all LEDs will be off. Operation

of the motor is now possible. If all four LEDs are flashing

simultaneously, SW6 is not configured correctly. Reconfigure

SW6 then turn off, then on, the toggle switch to restart.

10. Press the Start/Stop push button once. The RUN LED (led1)

will blink indicating that the motor has been started. The

motor at this point may not be rotating because minimal

voltage is being applied to the motor.

11. Slowly increase the voltage on the motor by rotating the

potentiometer, R13, to the right (CW). At some point the

motor will start to rotate slowly. The actual starting voltage is

dependent on the specific motor being used.

12. If the motor is vibrating back and forth instead of rotating, it

is possible that the Hall sensors or the motor leads were not

connected correctly. If the correct switching sequence has

been selected, all that should be necessary to correct this

misbehavior is to swap two of the motors lead (or to swap two

of the Hall sensor leads).

13. Continue to rotate the pot until the motor is running at a

moderate speed of roughly 25%. Do not run the motor with

maximum voltage until the setup check-out is completed.

14. Press again the START/STOP push button. The motor will free

wheel to a stop and the blinking led1 will turn off.

15. Press again the START/STOP button. The motor will

accelerate to the previous run speed (assuming that the

potentiometer was not rotated). The blinking led0 will also

turn on.

16. While the motor is running, press the REVERSE button. The

RUN LED (led1) will turn off and the REVERSE LED (led2) will

turn on without blinking. After a short pause while the motor

is freewheeling to a stop, the motor will restart rotating in the

opposite direction. The RUN LED will be blinking and the

REVERSE LED will continue to be on.

17. Press again the REVERSE button. As before, the motor will

stop. But this time the REVERSE LED will turn off. After a

pause, the motor will restart but this time rotating in the

forward direction.

18. While the motor is running, the motor can be hard braked by

pressing the BRAKE push button.

The BRAKE LED (led3) will be on without blinking. When the

motor is restarted, the BRAKE LED will turn off.

CAUTION: This braking method turns on simultaneously all of

the low side bridge FETs. This will force the motor to a very

rapid stop. It the motor is loaded, or if the motor is not

designed for a rapid stop, mechanical damage to the motor

or to the load can result. If you are not sure about using this

braking method, only apply the brake when the motor speed

is relatively slow.

19. If, while operating the motor turns off, and all 4 LEDs are

blinking, the current limit shut-down has been activated after

255 consecutive pulse-by-pulse current limits. This may

happen if the motor speed (with load) is accelerated too

quickly, or if there is a fault with the motor or connections, or if

the motor is stalled. The iLimit LED will turn on momentarily by

itself if the overcurrent duration is less than 255 pulse-by-pulse

current limits.

It is now safe to proceed with testing at higher power levels or

speeds.

DC Motor Setup (Full Bridge)

The HIP2103-4DEMO1Z can also be used to drive a conventional

brushed DC motor. The setup procedure is essentially the same

as the BLDC configuration except that Hall sensor inputs are not

used and only two motor connections are used, MB (TB4) and MC

(TB5). When configured in a full bridge topology, phase A (MA) is

disabled by setting the corresponding HIP2103 to sleep.

To setup the motor driver for a full bridge topology, set SW6:2 to

on and switches SW6:0, 3, 4 to off. Refer to Table 1 for complete

configuration details for SW6.

As with the BLDC configuration, the motor rotation direction can

be controlled. But unlike the BLDC configuration, the motor can

be reversed even if it has not yet stopped rotating. Be cautious

when reversing the motor before it has stopped rotating.

The motor can also be braked by grounding both motor leads

similar to the BLDC motor.

DC Motor Setup (Half bridge)

The HIP2103-4DEMO1Z can also be used to drive a conventional

brushed DC motor with a half bridge Topology. The setup

procedure is essentially the same as the BLDC configuration

except that Hall sensor inputs are not used and only two motor

connections are used, MB (TB5) and the negative connection of

led1

led3

led2

At initial turn on, leds will turn on and

off one at a time starting with led1

led4

led1

led3

led2

led4

SW6 is not configured corrrectly

led1

led3

led2

While the motor is rotating, the RUN LED is blinking

RUN

REVERSE

BRAKE

led4

i LIMIT

led1

led3

led2

RUN

REVERSE

BRAKE

led4

i LIMIT

led1

led3

led2

RUN

REVERSE

BRAKE

led4

i LIMIT

led1

led3

led2

RUN

REVERSE

BRAKE

led4

i LIMIT

led1

led3

led2

RUN

REVERSE

BRAKE

led4

i LIMIT