8

D

C

B

A

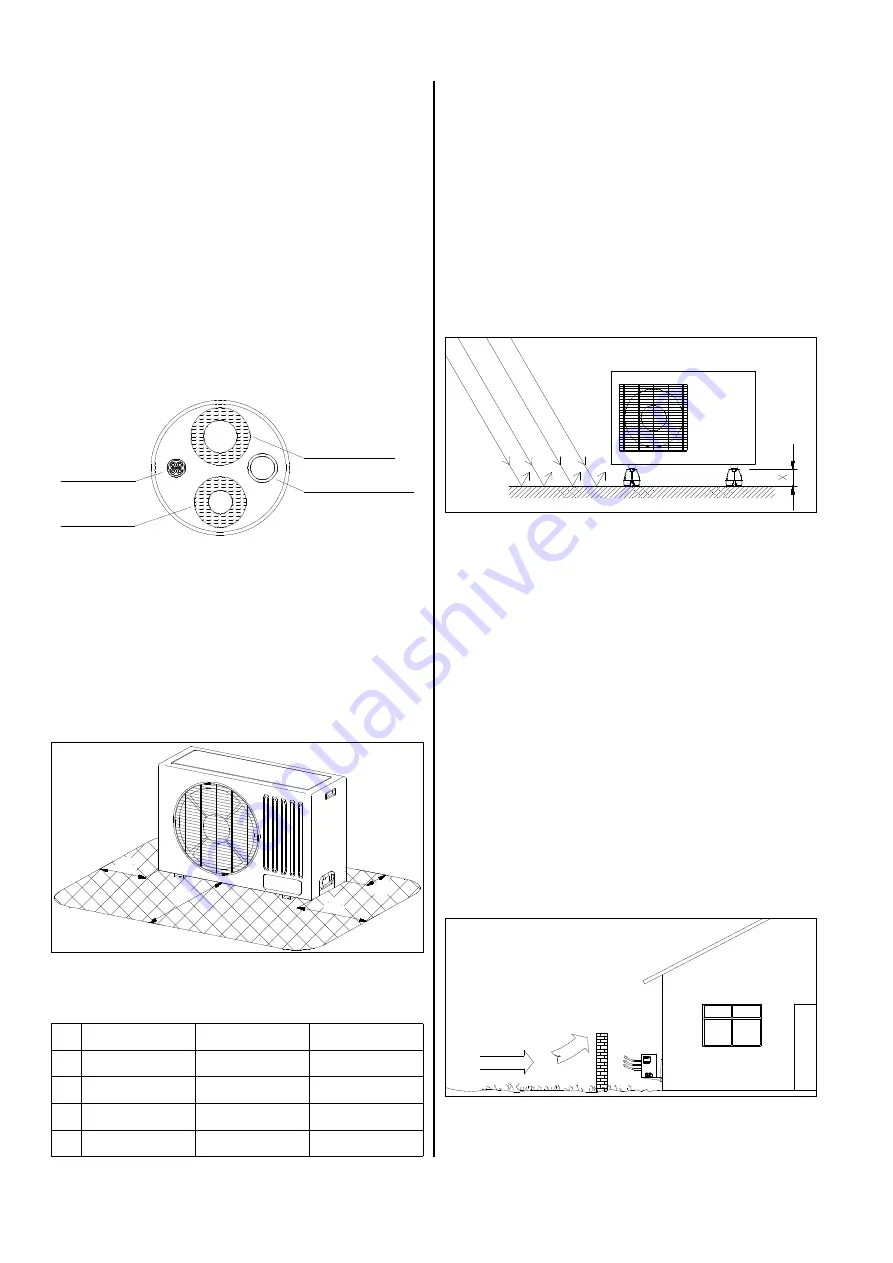

RKS 510

RKS 513

RKS 524

A

200 mm

200 mm

300 mm

B

700 mm

700 mm

900 mm

C

400 mm

400 mm

400 mm

D

100 mm

100 mm

200 mm

Wind

These safety zones ensure that air can flow freely in and

out of the unit, that maintenance and repair work can be

performed and to protect the unit from damage.

Minimum distances

The figure below indicate the minimum distances that

must be maintained to ensure that the units operate

properly.

Wall lead-throughs

Wall lead-throughs are necessary to establish the con-

nection between the indoor unit and the outdoor part.

Please observe the following:

◊

For the connection line to the outdoor part, a lead-

through of at least 70 mm in diameter per cold cycle

must be created.

◊

The lead-through must be placed at an incline of at

least 10 mm between the inside and outside.

◊

Before beginning work, make sure that there are no

supply lines (water, etc.) located in the vicinity of the

wall lead-through.

◊

We recommend cushioning the inside of the hole or

lining it with a PVC pipe to prevent damage to the

lines.

Control lines

Refrigerant

return line

Condensation tube

Refrigerant

supply line

◊

After assembly is complete, the wall lead-through

must be sealed with a suitable sealing compound.

Do not use any materials containing cement or lime!

Location of installation for the outdoor part

The outdoor part must be set up on a surface that is

level, smooth and solid.

The outdoor part can either be set up outside or inside a

building. If it is set up outside, follow these instructions

to protect the unit from weather conditions.

This prevents dirt and rust caused by splashing rain.

Rain:

If the outdoor part is set up on the ground or a roof,

there must be at least 10 cm ( measurement X in the

illustration below) between it and the surface.

A base console can be purchased as an accessory.

Sun:

The plate fin exchanger (condenser) on the outdoor part

is a heat-emitting component.

Direct sunlight also increases the temperature of the

plate fins and reduces the amount of heat expelled by

the plate fins exchanger.

If possible, the outdoor part should be installed on the

north side of the respective building.

A small structure should be set up to provide shade for

the unit and protect it from the sun if necessary. How-

ever, it must not be allowed to interfere with the flow of

hot air being released from the unit.

Wind:

If the outdoor part is operated primarily in windy areas,

make sure that the hot air current being released from

the outdoor part is flowing in the primary wind direction.

If this is not possible, you should provide protection from

the wind. Make sure that the wind protection does not ad-

versely affect the flow of the air to the unit.

Summary of Contents for RKS 510

Page 2: ......