24

Length of line

Amount per meter

Up to and including 5 m

–––

5 m up to and including 15

m

30 g/m

Adding Refrigerant

The refrigerant required for operating the system is lo-

cated in the outdoor part.

For refrigerant lines longer than 5 m per cycle, refriger-

ant must be added using the following table:

Proceed as follows to add additional refrigerant:

1. Remove the vacuum pump and connect the filling

cylinder.

2. Place the open cylinder on a scale and calibrate the

scale to zero.

3. Create a vacuum in the hose at the height of the ma-

nometer distribution pipe.

4. Use the table above to determine the quantity to add

to begin the filling process.

5. Close the manometer valve when the appropriate

amount has been added.

Initial Operation

Initial operation of the unit must be performed by the

manufacturer or and authorised service centre and must

comply with the certification specifications and be docu-

mented.

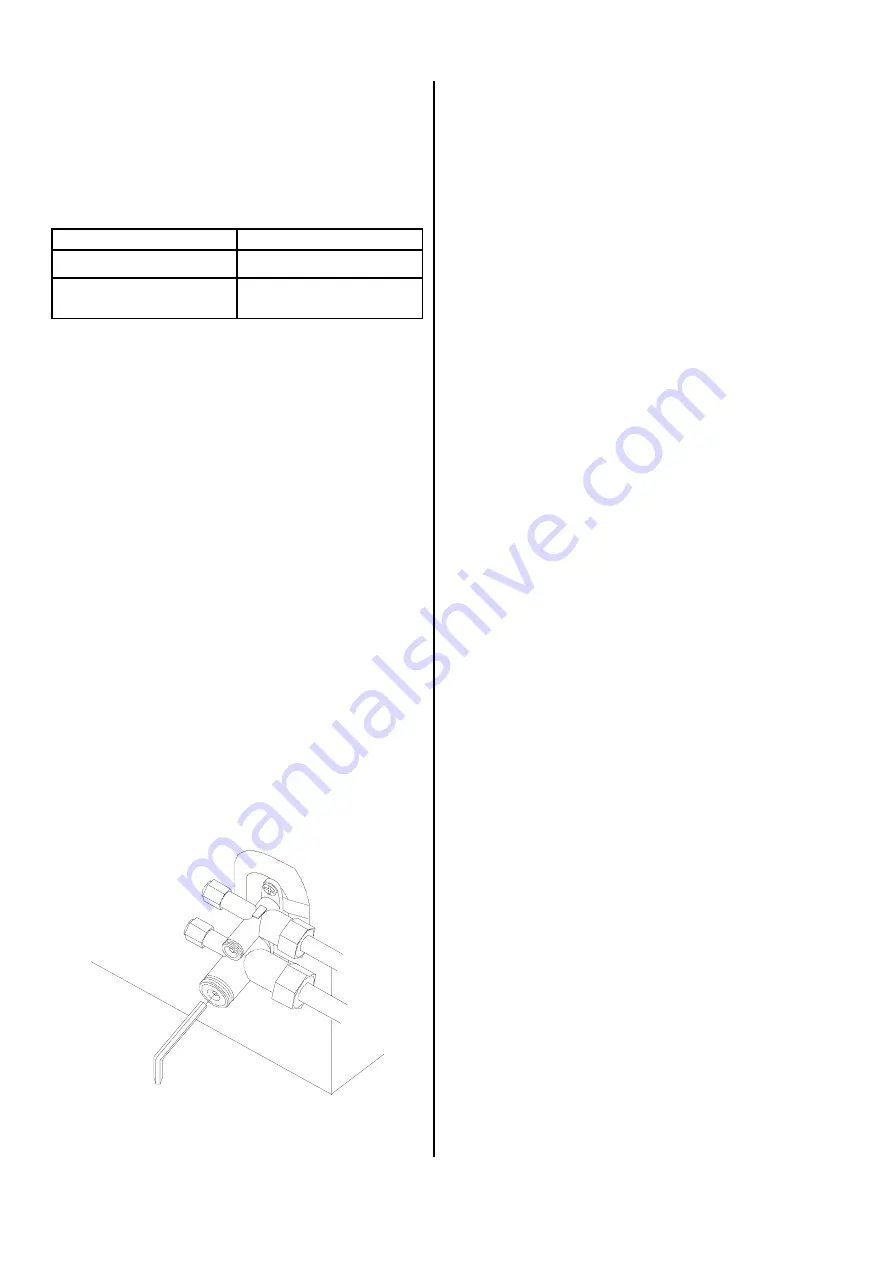

1. Remove the caps from the shut-off valves.

2. To begin initial operation, open the shut-off valves of

the outdoor part.

4. Do a test run

For more information, see the following section.

5. Measure all the required values and complete the

initial operation log.

6. Remove the manometer station.

7. Replace the caps.

Functional check and test run

The functional checks are started via the indoor unit.

The indoor unit runs in standard cooling operation for

the test.

Check the following items:

à

Check refrigerant lines for leaks.

à

Check that the ventilator and compressor are run-

ning evenly.

à

Check that cold air is being expelled from the indoor

unit and warm air from the outdoor part.

à

Conduct a functional test of the indoor unit and all

program processes.

à

Check the surface temperature of the suction line

and determine the evaporator overheating value.

To measure the temperature, hold the thermometer

on the suction line and subtract the boiling point tem-

perature recorded on the manometer from the meas-

ured temperature.

à

Document the measured temperatures in the initial

operation log.

Proceed with the test run as follows:

1. Switch the customer-installed main switch or fuse

on.

2. Adjust the target temperature on the indoor unit to a

lower value than the existing room temperature us-

ing the remote control.

3. Switch the unit to the cooling mode by pressing the

MODE button.

3. Open the shut-off valves all the way with a hexagonal

wrench by turning them counterclockwise.

4. During the test run, check all regulating, control and

safety mechanisms to ensure that they are function-

ing and set properly.

5. Check the indoor unit’s control mechanism using the

functions described in the section “Operation”.

Timer, temperature settings, fan mode and dehu-

midifying mode as well as all other mode settings.

6. Familiarise the operator with the system.

7. Give the operator the filled out certificate for initial

operation.

G

The compressor starts a couple of minutes later

due to the delayed start of the outdoor part.