CB40E Gas Fireplace

VENTING INTRODUCTION

The CB40E uses the "balanced flue" technology Co-Axial system. The inner liner vents products of combustion to the outside while the outer liner

draws outside combustion air into the combustion chamber thereby eliminating the need to use heated room air for combustion and losing warm room air

up the chimney.

Note: These flue pipes must not be connected to any other appliance.

The gas appliance and vent system must be vented directly to the outside of the building, and never be attached to a chimney serving a separate solid fuel

or gas burning appliance. Each direct vent gas appliance must use it's own separate vent system. Common vent systems are prohibited.

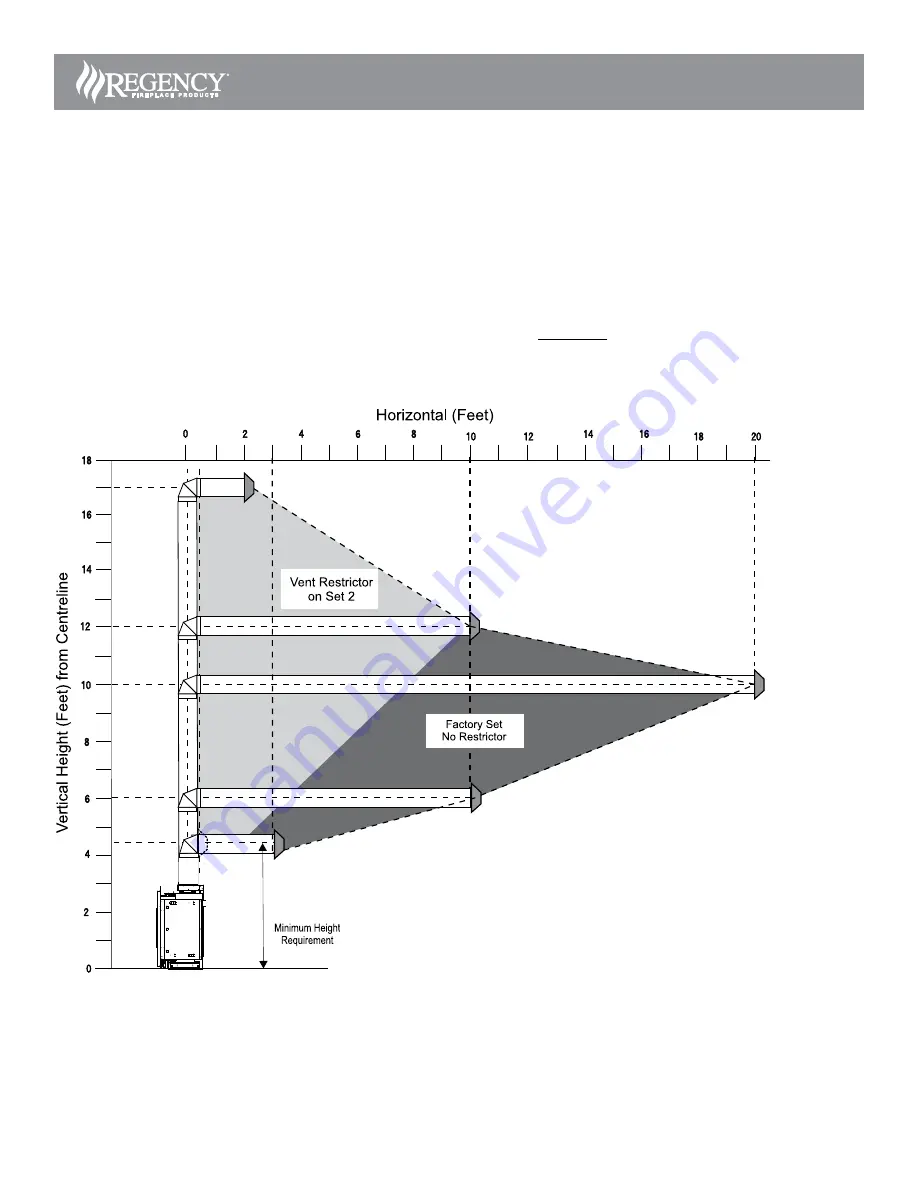

VENTING ARRANGEMENT FOR HORIZONTAL TERMINATIONS

The diagram shows all allowable combinations of vertical runs with horizontal terminations,

using one 90

o

(two 45

o

elbows equal one 90

o

elbow).

Note:

Must use optional rigid pipe adapter (Part# 510-994) when using Rigid Pipe Venting Systems)

• Maintain clearances to combustibles as listed in "Clearances" section

• Horizontal vent must be supported every 3 feet.

• Firestops are required at each floor level and whenever passing through a wall.

• A vent guard should be used whenever the termination is lower than the specified minimum or as per local codes.

• Flex system can only be used up to 10 feet - otherwise rigid venting must be used.

VENT RESTRICTOR SETTING:

Vent restrictor factory set at Set 0.

Refer to the "Vent Restrictor Position" section for details on how to change the vent restrictor from the factory setting of Set 0 to Set 2 if required.

NOTE: A minimum of 1' (305mm) vertical off the top of the unit is required before any horizontal runs can start.

Note: For horizontal terminations the Regency Direct Vent Flex System may be used for installations with a maximum continuous vent

length of up to 10 feet. If longer runs are required, rigid pipe must be used.

56-1/4” (1429mm)