10

|

Regency U31-10 Gas Fireplace Insert

|

10

installation

MINIMUM FIREPLACE

DIMENSIONS

The minimum fireplace dimensions for the FPI gas

fireplace insert are shown in the following diagrams:

8-1/8

”

Low profile

Standard

Faceplate

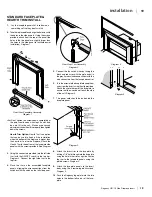

INSTALLATION

CHECKLIST

The Regency Gas Insert is installed as listed below.

1.

Unit Location - check Clearances to Combus-

tibles.

2.

Make the gas connections.

Convert to Propane Gas if necessary.

3.

Install the flue or liner to the sliding draft hood.

4.

Install Venting. Slide the unit into the fireplace.

Attach draft hood to the insert.

5.

Test gas pressure.. Check aeration

6.

Test for flue spillage.

7.

Install the optional brick panels.

8.

Install the log set.

9)

Assemble and install the faceplate.

10)

Install the glass front.

11)

Install Safety Screen, Remote Control and

Optional Wall Thermostat.

12

)

Final check:

Before leaving this unit with the

customer, the installer must ensure that the

appliance is firing correctly. This includes:

a)

Clocking the appliance to ensure the

correct firing rate.

b)

Adjusting the primary air, if required, to

ensure that the flame does not carbon.

c)

Ensuring that the appliance is venting

correctly.

MATERIALS REQUIRED

No electrical power supply is required for the gas

control to operate. A 120 Volt AC power cord is

hooked up to the fan. Plug the 3 wire cord into a

suitable receptacle.

Do not cut the ground terminal

off under any circumstances.

When connected

with 120 volts, the appliance must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the current Canadian

Electrical Code CSA C22.1 (in Canada) or with

the current National Electrical Code ANSI/NFPA

70-1987 (in U.S.A.).

CLEARANCES TO

COMBUSTIBLES

From Unit

Sides

A

10" / 255 mm

Ceiling

B

47.5" / 1205 mm

Mantle

C

See mantle

clearances

Max. Mantel Depth

G

12" / 305 mm

Min. Alcove Width

K

48" / 1220 mm

Max. Alcove Depth

L

36" / 915 mm

* No Hearth Required

NOTE: This unit is equipped with a heat sensor

thermodisc which will prevent the blower

from operating until the unit reaches the

correct temperature.

Summary of Contents for Energy U31-LP10

Page 1: ......

Page 5: ...4 Regency U31 10 Gas Fireplace Insert 4 dimensions UNIT DIMENSIONS WITH STANDARD FACE PLATE ...

Page 33: ...32 Regency U31 10 Gas Fireplace Insert 32 notes ...

Page 34: ...Regency U31 10 Gas Fireplace Insert 33 33 notes ...

Page 35: ...34 Regency U31 10 Gas Fireplace Insert 34 notes ...