© 2006

GE ECM

by Regal-Beloit

- 36 -

Indoor Blower Motors

v0.2

If the manufacturer provides the information in their troubleshooting guides as to

what these dc voltages should be, the communication can be diagnosed with a dc

volt meter. Make sure the meter is set to dc volts and the polarity of the connections

is correct following the OEM guides.

The information provided below is strictly “nice to know” information. A

technician would not make the following checks to diagnose the motors

operation or output.

-

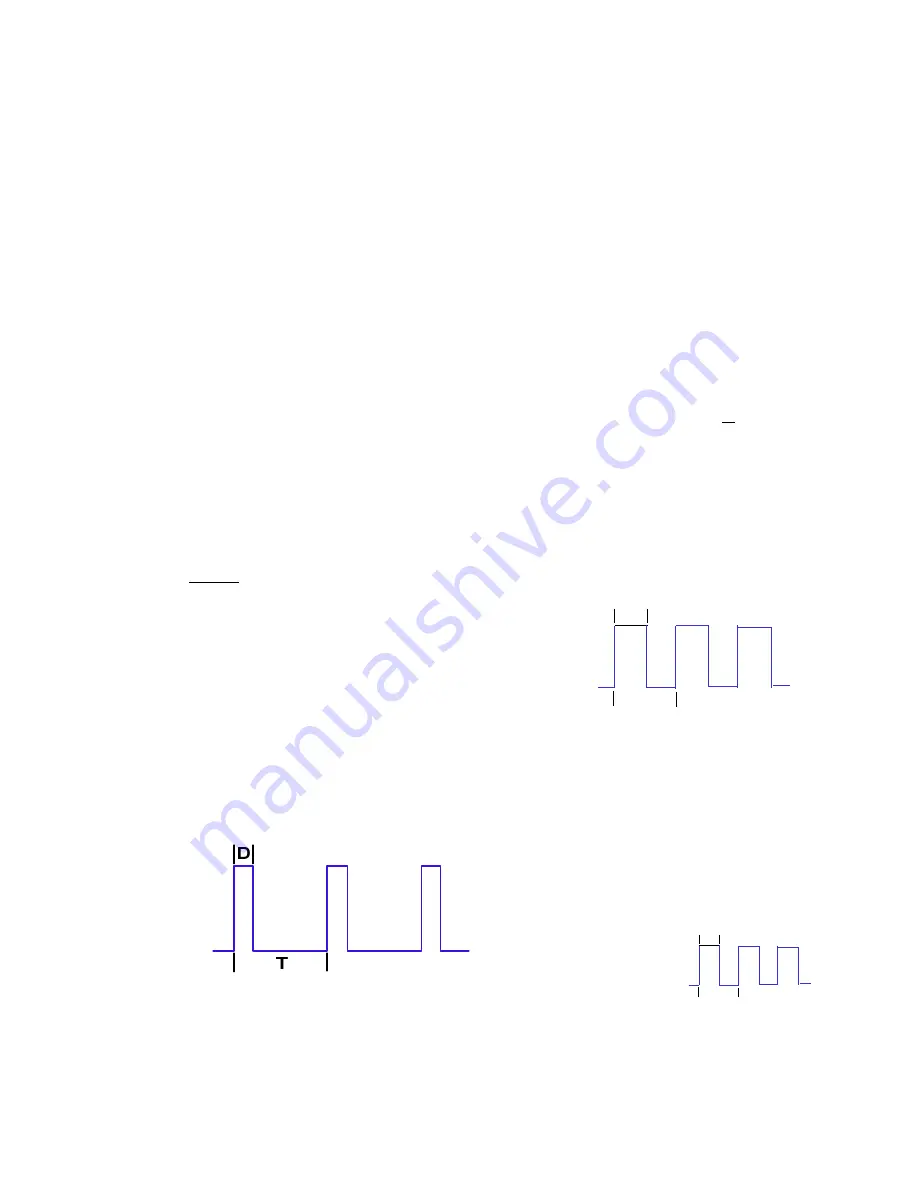

The motor does not look at the dc voltage on the PWM circuit. It is reading the

duty cycle as a representation of the desired motor output.

The following formula can be applied to the dc voltage readings to help

understand the % demand of the PWM signal (duty cycle)

For Example:

20 vdc is measure between terminals 3 and 15 (value T)

10 vdc is measure between terminals 3 and 10 (value D)

The percentage of demand (motor output or airflow) would be 50%.

10 (D) = .5 x 100 = 50%

20 (T)

The actual PWM signal would look like the example to

the right, where the signal is on for 50% of the cycle

and off for 50% of the cycle.

If the demand percentage was 20% the PWM signal

would be on for 20% of the cycle and off for 80% of

the cycle. This signal would like the example to the

below.

PWM (Duty Cycle)

D

T

Pin number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Connected to PWM common

NC*

Connected to PWM common

NC*

NC*

NC*

NC*

NC*

NC*

PWM signal

NC*

NC*

NC*

NC*

Start/Stop signal: 9 - 23VDC

NC*

* Not Connected

Pin number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Connected to PWM common

NC*

Connected to PWM common

NC*

NC*

NC*

NC*

NC*

NC*

PWM signal

NC*

NC*

NC*

NC*

Start/Stop signal: 9 - 23VDC

NC*

* Not Connected

PWM (Duty Cycle)

D

T

% Demand = x 100

(in torque or airflow)

D

T