Controller

24 — English

Reflexomat XS — 02.16.2022 - Rev. A

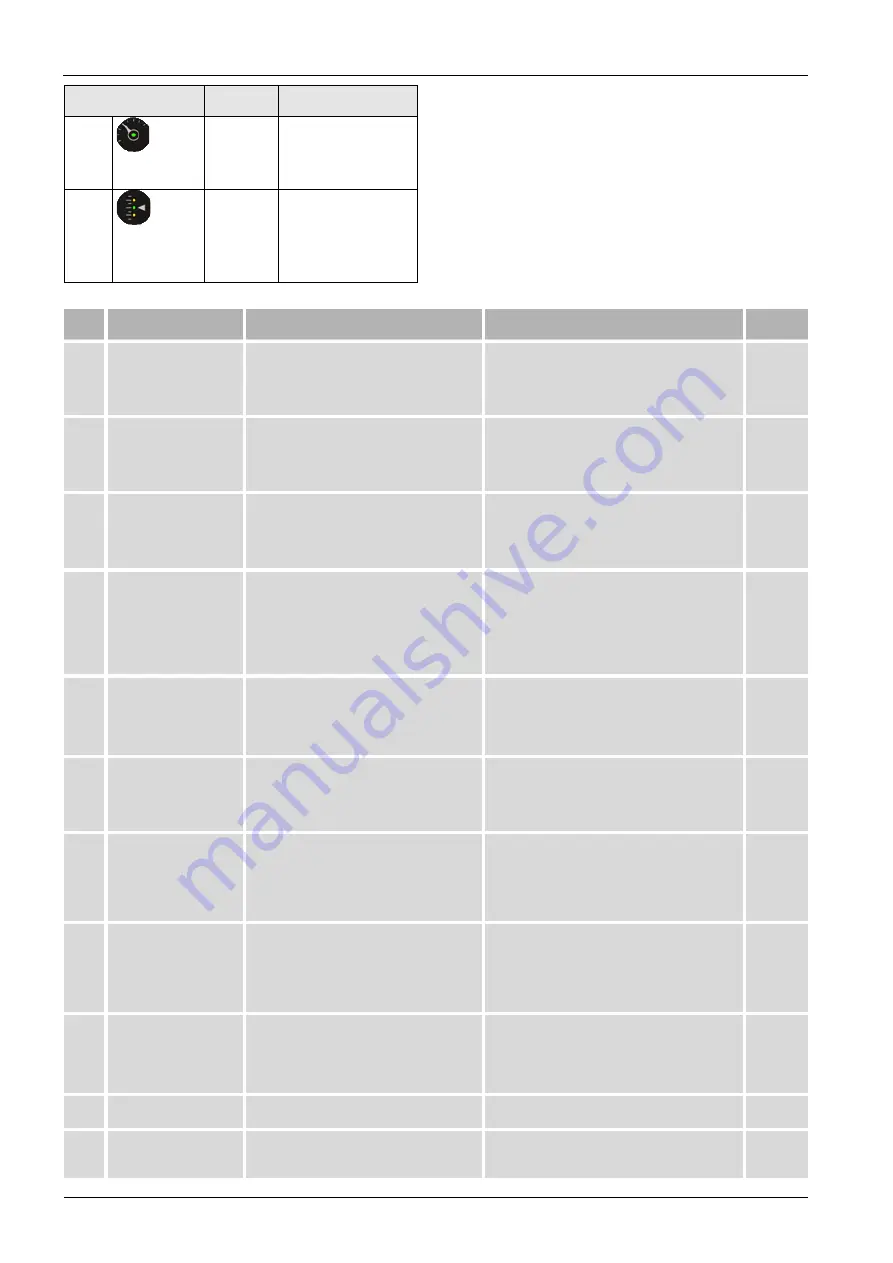

LED

Function /

display

Meaning

Pressure

LED lights up

LED flashes

Automatic operating mode

Fault (min. pressure,

defective pressure

measurement, deviation

from set pressure, etc.)

Level

LED lights up

in green

Automatic operating mode

LED lights up

in yellow

Warning (make-up request,

high water)

LED flashes

yellow

Fault (low water, weight

measuring cell defective)

Alarm causes can be eliminated by the operator or a specialist workshop. If this is

not possible, contact the Reflex Customer Service.

Note!

Elimination of the cause must be confirmed via the service button on the

control panel of the controller. All other alarms are automatically reset as

soon as the cause has been eliminated.

ER

Code

Alarm

Causes

Remedy

Alarm reset

01

Minimum pressure

[1] Auto LED lights up

[5] Error LED lights up

[2] Pressure LED flashes

Set value p

0

not reached:

•

Compressor fault.

•

Air side leak of the system.

•

Check the functioning of the compressor.

•

Check the sealing points for leak tightness.

-

02.1

Low water

[1] Auto LED lights up

[5] Error LED lights up

[3.3] Level LED flashes

Too little water in the vessel (filling level <5%):

•

Make-up disabled.

•

Water loss in the system.

•

Filling level measurement defective.

•

If necessary, manually add water.

•

Check water level.

-

03

High water

[1] Auto LED lights up

[5] Error LED lights up

[3.1] Level LED lights up

Filling level >90%:

•

Make-up function defective (continuous water

supply)

•

External water entry through the system (e.g.

defective heat exchanger)

•

Check the make-up unit.

•

Check functioning of the "PV" solenoid valve.

•

Drain water from the vessel.

•

Check on-site heat exchanger for leakage.

-

05

Compressor run time

[1] Auto LED flashes

[4] Stop LED flashes

[5] Error LED flashes

[2] Pressure LED flashes

[3] Level LED off

Maximum compressor run time exceeded:

•

Air side leak.

•

Compressor has no power.

•

Check the water loss and correct, if necessary.

•

Seal any leak in the air system.

•

Check functioning of "PV" air side solenoid valve.

•

Check functioning of compressor.

"Service"

06

Make-up time

[1] Auto LED lights up

[5] Error LED lights up

[3] Level LED flashes

Set max. make-up time has been exceeded:

•

Water loss in the system.

•

Automatic make-up not connected.

•

Make-up output insufficient.

•

Make-up hysteresis too high.

•

Check the set values.

•

Check automatic make-up.

•

Check water level.

•

Connect make-up line.

•

Seal any leakage in the system.

-

07

Make-up cycles

[5] Error LED lights up

[4] Stop LED lights up

[3.3] Level LED lights up

Number of set max. make-up cycles has been

exceeded:

•

Leakage in the system.

•

Check the set value.

•

If necessary, manually add water.

•

Check system for leakage.

-

08

Pressure measurement

[1] Auto LED off

[4] Stop LED flashes

[5] Error LED flashes

[2] Pressure LED flashes

•

Controller receives incorrect signal.

•

Check the plug connection at the pressure sensor.

•

Check functioning of the pressure sensor.

•

Compare the values from the app with the pressure

gauge

•

Check the cable for damage.

-

09

Filling level measurement

[1] Auto LED off

[4] Stop LED flashes

[5] Error LED flashes

[3] Level LED flashes

•

Controller receives incorrect signal from the

weight measuring cell.

•

Check the plug connection at the weight measuring

cell.

•

Check the functioning of the weight measuring cell.

•

Check the cable for damage.

"Service"

10

Maximum pressure

[1] Auto LED lights up

[2] Pressure LED flashes

[5] Error LED lights up

Set value (P

Sv

-0.3 bar) exceeded:

•

Air side solenoid valve does not blow off.

•

Compressor runs continuously.

•

Check the set values.

•

Check system-side water connection.

•

Check functioning of air side solenoid valve.

•

Clean the silencer of the air-side solenoid valve.

•

Check the compressor relay.

-

11

Make-up quantity

Specified make-up quantity has been exceeded

•

Severe water loss in the system.

•

Check system for leakage.

-

15

Make-up valve

Contact water meter measures without make-up

request

•

Check system for leakage.

•

Clean make-up valve.

•

Replace make-up valve (if necessary).

-

Cooke Industries - Phone: +64 9 579 2185 Email: [email protected] Web: www.cookeindustries.co.nz