17

11.0

TROUBLE SHOOTING (PROBLEM ANALYSIS)

Problem Possible

cause

Solution

Too much damage to the

processed ground

Knives are damaged.

Knives are adjusted too

deeply.

Try to repair the knives.

Mount new knives.

Adjust the working depth.

Knives are crooked.

Straighten the knives.

Mount new knives.

Another knife setting.

Not driving in a straight line.

Try to drive in a straight line.

Soil is too wet.

Postpone the work until the soil is

dry.

Felt layer / substrate not

sufficiently cut.

Knife adjustment is too

shallow.

Knives are blunt.

Change the knife adjustment.

Sharpen the knives.

Mount new knives.

Ground is too hard/dry.

Use a different knife adjustment.

Fill the container with additional

weight / give water first.

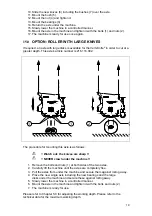

12.0

MAINTENANCE

Only authorised technical personnel may carry out repairs or adjustments to the

Verti-Knife

®

due to the safety of the machine and the user.

With regards to the safety of the machine and the user, use only original

Verti-Knife

®

parts

for maintenance and repairs.

Time schedule

Check point

Method

Before

every

use

Check for loose bolts / nuts.

Tighten loose bolts / nuts.

After

every

20 working

hours

Check for broken or bent knives. Repair or replace the knives.

Check for loose bolts / nuts.

Tighten loose bolts / nuts.

Presence and readability of the

safety stickers

(See Figure 5)

Replace if these are

damaged.

Grease the bearings.

Use EP2 lubrication.