13

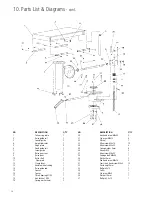

Fig. 5.1

D

B

F

E

C

A

Fig. 5.2

C

A

B

General information

Safety instructions

Before every use, check:

• All required guards are properly installed.

• All clamping screws of the blade holders are tight (minimum tightening

torque: 15 Nm).

• That you are always using sharp planer blades (minimizes the risk

of kickback).

• That the individual anti kickback guards can move freely and fall back

into their initial position after being lifted. (appllies only to thicknesser

function)

• Use auxiliary devices when working short and narrow pieces (e.g. push

stick or safety feed blocks).

Remaining risks

The following risks remain when working with the planer thicknesser

despite observing the appropriate protective measures:

• Danger of injury when changing blade.

• Observing of injury due to contact with the rotating planer cutterblock.

• Danger of injury due to ejected workpieces.

• Danger of injury due to workpiece kickback.

• Hearing danger due to high noise levels.

• Health risks due to dust emission during work especially when processing

beech and oak.

Working techniques

Permitted working techniques.

All uses deviating from those described below are considered improper uses

and are therefore not permitted.

• Planing the wide side of a workpieces.

• Planing the narrow side of a workpieces.

• Bevelling the edges of a workpieces.

Prohibited Working Techniques

The following work techniques are prohibited on the machine.

• Down-cut jointing (direction of arbor rotation same as feed direction).

• Insertion cuts (workpiece is not worked along its entire length).

• Planing of excessively warped timber.

• Thickness planing of multiple workpieces of different thicknesses.

Planer Bridge Guard

The planer bridge guard consists of the protective guard plate (A -

Fig. 5.1

),

the planer bridge guard arm (B -

Fig. 5.1

),

and support bracket (C -

Fig. 5.1

).

The height and width of the protective rail is continuously adjustable.

Height adjustment (arm tilt): set Star knob screw (D -

Fig. 5.1

).

Width adjustment: Star- knob screw (E -

Fig. 5.1

).

Star - knob screw (F -

Fig. 5.1

) is adjusted to keep the guard level.

Setting the Planer Table

The Feed Table Adjustment

Open table lock (A -

Fig 5.2

). Turn adjusting handle (B -

Fig 5.2

) until

you can see the desired value on scale (C -

Fig 5.2

) (maximum 4 mm)

Re-tighten the table lock securely.

5. Operation

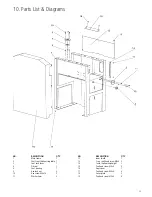

Summary of Contents for PT107

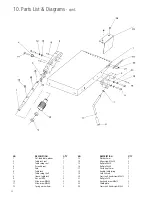

Page 29: ...29 10 Parts List Diagrams cont ...

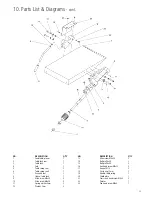

Page 33: ...33 ...