1 - Overview

Overview

This manual covers the operation of the Pro-Series 8000 when configured as an Apollo

8000 Variable-Rate Spray Controller. Separate manuals are supplied for other

applications. The "Delta 34" instrument has identical sprayer control functions and

capabilities with the exception of Data Logging. This menu is not available.

1.1

The RDS Precision Farming System (Apollo only)

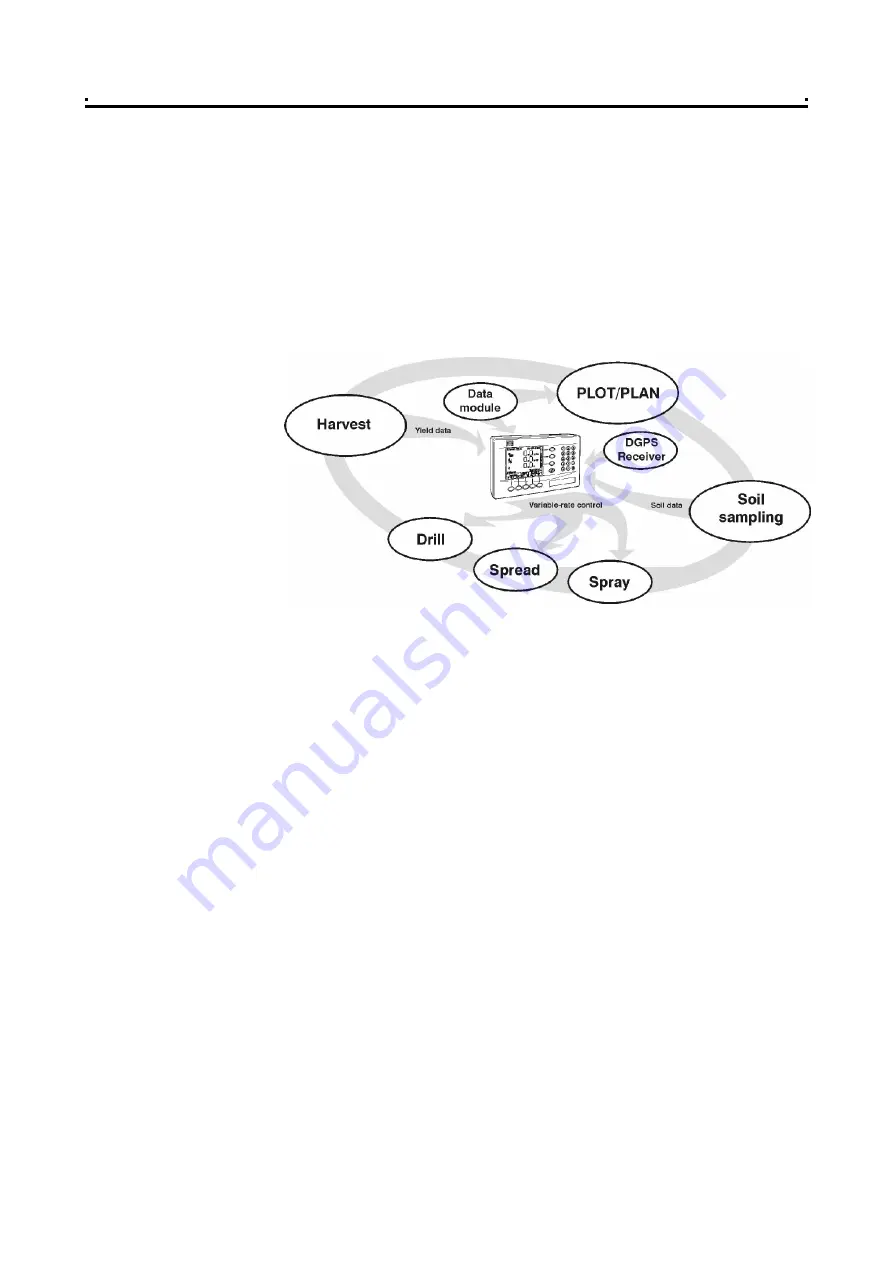

The RDS

PS 8000

is a fully DGPS compatible, multi-function cab computer for a wide

range of applications and is the central component of RDS Precision Farming

hardware (figure 1).

1.2

Installation and Inter-operability with other systems (Apollo

only)

An RDS control system comprises several component kits. This modular approach

means that a suitable control system can be specified for a very wide range of

implements. When re-configured with the appropriate control software the

PS 8000

head unit can be simply transferred between different implements.

The

PS 8000

can also output variable-rate instructions to other control systems

including Vicon, Bogballe and Amatron systems, as well as acting on variable-rate

instructions received from Fieldstar, Soyl Opti, Agrocom ACT and Hydro-N Sensor

systems.

1.3

Control Software (Apollo only)

Your instrument is pre-loaded with "Apollo Sprayer Control" software only.

With the purchase of a "secondary software module" - an electronic chip loaded into

the back of the instrument, the Pro-Series can be instantly switched to perform

another function e.g. from a Sprayer Controller to a Data Logger for route navigation

and soil mapping tasks. This is done from "

Instrument Select

" in the "USER

OPTIONS" menu.

There are software modules for yield monitoring/mapping, route/soil mapping,

variable-rate sprayer control, variable-rate belt spreader control, variable-rate disc

spreader control, and variable-rate seed drilling.

For information on connecting and configuring RDS PF

hardware

e.g. the Data Card

Module, Secondary Software Module, DGPS Receiver, cables etc, and data transfer

to your PC, please refer to the "Precision Farming Supplement".

1

Figure 1

The Pro-Series 8000 is the

central component of RDS

Precision Farming hardware

4