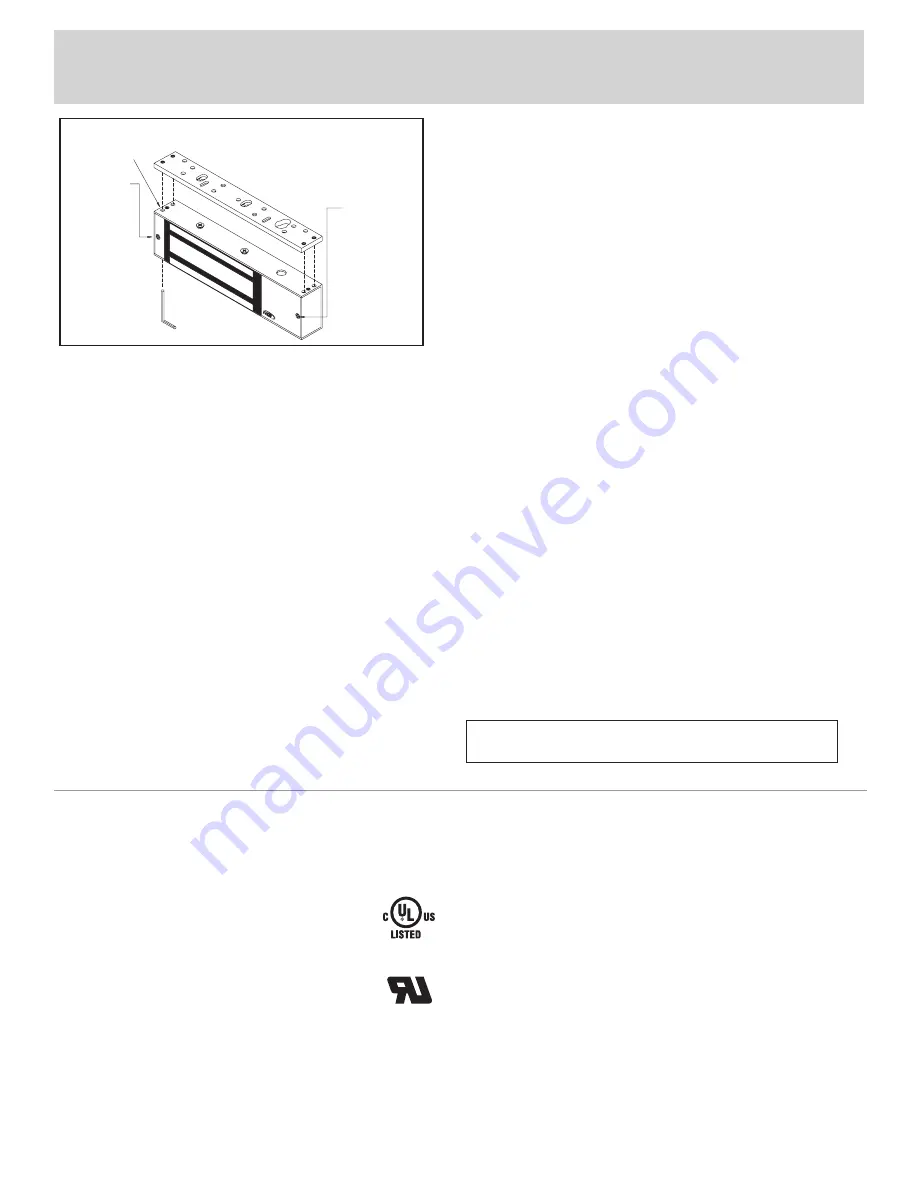

3

Anti-Tamper Feature - Two screws prevent insertion of an Allen

wrench into the captive mounting screw opening on the bottom of

the lock. Fig. 3 shows their location. one screw also secures the

wiring cavity cover. The mounting plate cannot be separated from

the lock without removing these two screws.

Lock Options

Both of the 8310 and 8320 locks can be equipped with the DSS or SCS

options or both.

SCS (Security Condition Sensor) - This feature can detect the quality of

the locking bond between the surface of the magnet and the armature

plate. Indication is with a local leD as well as remote monitoring

through a SPDT relay output. The sensitivity of this feature is such that

a foreign object with a thickness of .007” (.18mm) is sufficient to allow

the sensor to detect a problem.

Due to the sensitivity of this feature and the necessity to maintain a

reliable locking bond, these surfaces must be kept free of contaminating

materials. Both the lock surface and the armature plate must be cleaned

periodically with a non-abrasive cleanser. Alignment of armature plate

and magnet is required to ensure proper function of sensor.

Low Voltage Detection - each SCS circuit board also includes a low

voltage detection circuit when shipped from the factory. This

feature will cause the alarm relay and status leD to activate

should the lock input voltage drop below 9vDC. That signals a

monitored system or guard station that the holding force of the

lock may have been compromised.

DSS (Door Status Sensor) - The DSS option monitors the position

of the door upon which the lock is installed. A SPDT reed switch

mounted within the lock cavity eliminates the need for extra sensors

to be installed on the door for notification of security or access control

systems. The DSS option comes with a magnet pre-installed into the

lock armature plate for signaling the reed switch in the housing when

the door is closed independent of power to the lock. Care should be

taken during the final testing of the lock to ensure that the DSS option

is operating in the desired manner.

Inspection and Maintenance

This product and all related accessories or parts must be inspected

and maintained on a quarterly basis. Contacting surfaces of the

electromagnetic lock and armature plate must be kept free of

contaminating materials. Surfaces must be cleaned periodically with a

non-abrasive cleaner.

All mounting fasteners must be inspected on a quarterly basis.

When properly installed, the ends of the armature plate allow a slight

movement but the plate will feel secure when grasped at the bolt. There

should be no movement to the mounting bracket or housing of the

electromagnetic lock.

For added safety, thread locking compound has been provided for the

armature plate bolt and the four captive electromagnetic lock mounting

screws.

WARNING: Improper installation, maintenance, inspection or usage

of the product or any related accessories or parts may cause the

electromagnetic lock, armature plate and associated hardware to

disengage and fall, causing serious bodily injury and property damage.

PleASe DelIveR All INSTAllATIoN INSTRuCTIoNS To

tHe eND-user upoN completIoN of tHe INstallatIoN.

8310 & 8320 Electromagnetic Lock

Installation Instructions

(Continued)

Listings

These products have been successfully tested and evaluated by ul

in two separate categories for use in both the united States and

Canada.

auxiliary lock. the GWXt fire listing qualifies these for

use with ul Classified fire doors maximum 4’ in width

and 8’ in height. The 8310 and 8320 are rated up to and

including 1-1/2 hours (90 minutes).

Special locking Arrangement Component. Additionally,

these products are qualified components for the purpose

of locking outward-swinging exit doors against unauthorized egress.

They are designed to release automatically in case of a power failure

or upon activation of an automatic fire alarm system wired to the

power supply fire panel relay.

The Following Conditions of Acceptability Apply:

1) This product is intended for use with Special locking

Arrangements which are installed in accordance with the

manufacturer’s installation and operation instructions, the life Safety

Code, NFPA 101 of the National Fire Protection Association and the

local authority having jurisdiction.

2) The power for this unit is to be provided by a listed (AlvY,

fula, or apHV) class 2 power supply when designated as a special

locking arrangement (fWaX).

3) The suitability of the lead wires is to be evaluated per the

requirements for the end-use product.

4) If the product is installed in conjunction with a fire alarm control

panel, the wiring from the control unit to this product device shall be

for fail-safe operation.

ul testing was conducted on standard models without accessories.

These locks are not intended or tested for use as a ul listed Burglar

Alarm System unit.

CAMERA-READY LOGOTYPE FOR TYPE L AND TYPE R LISTING MARKS FOR CANADA AND THE U.S.

These Marks are registered by Underwriters Laboratories Inc.

The minimum height of the registered trademark symbol ® shall be 3/64 of an inch. When the overall diameter of the

UL Mark is less than 3/8 of an inch, the trademark symbol may be omitted if it is not legible to the naked eye.

The font for all letter forms is Helvetica Condensed Black, except for the trademark symbol ®, which is

Helvetica Condensed Medium. No other fonts are acceptable.

Please Note:

The word "MARINE" should only be used for UL Classified marine products.

200-195F 20M/11/97

Fig. 3 – Lock Mounting

Anti-tamper

feature screw

Anti-tamper

feature and

wiring cavity

screw

Captive

mounting

screw