LCD INSTALLATION AND OPERATION INSTRUCTIONS

Page 27

OPERATING INSTRUCTIONS

1.

STOP!

Read the safety information above. If, at

any time, the appliance will not operate properly,

follow the instructions “TO TURN OFF GAS TO

APPLIANCE”.

2. Set the operating control or thermostat to off or its

lowest setting.

3. Turn off all electric power to the appliance.

4. Close the main manual gas shut-off valve, Figure 16.

5. Wait fi ve (5) minutes to clear out any gas. Then

smell for gas, including near the fl oor. If you smell

gas,

STOP!

Follow “B” in the safety information

above (to the left) on this label. If you do not smell

gas, go to the next step.

6. Remove the upper front jacket panel.

7. Turn the knob on the pilot valve to off, Figure 18.

8. Turn the knob on the main gas valve to off, 225

through 400 models, Figure 18. On 600 through

2300 models close the manual shutoff valve located

in the control compartment, Figure 19.

9. Remove the plug(s) from the pilot and manifold

pressure fi tting(s), Figure 19.

10. Connect a manometer having a minimum capacity

of

20 in

,

508 mm W.C

. to the pilot and manifold

pressure fittings, Figure 19. Make sure the gas

supply piping has been purged of air and all gas

joints up to the gas valve have been thoroughly

checked for leaks.

11. Remove plug(s) from the differential air pressure

taps, Figure 17.

12. Connect both sides of a manometer to the pressure

switch tee, Figure 17, going to one of the pressure

switches.

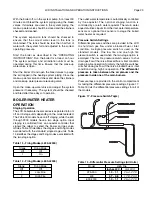

Figure 18 - Pilot Valve (All Models)

Main Valve (225 - 400 Models)

13. Turn the knob on the pilot valve to on, Figure 18.

14. Turn on all electric power to the boiler and set

the operating control or thermostat to the desired

setting.

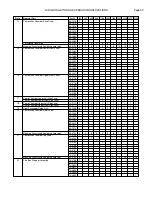

15. With the unit operating at high purge the differential

air pressure should match those listed in Table

15. To adjust the differential air pressure see the

“AIRFLOW ADJUSTMENT” instructions in the

“CHECKING AND ADJUSTMENTS” section.

Figure 19 - Manual Valve & Manifold Pressure Tap

16. The pilot should automatically light. Do not try to

light the pilot by hand!

17. The pilot pressures should match those listed

in Table 20. To adjust the pilot gas pressure see

the “PILOT ADJUSTMENT” instructions in the

“CHECKING AND ADJUSTMENTS” section.

18. Distinguish pilot.

19. Turn the knob on the main gas valve to on, 225

through 400 models, Figure 18. On 600 through

2300 models open the manual shutoff valve located

in the control compartment, Figure 19.

20. Recycle boiler.

21. The manifold pressures should match those listed

in Table 20. To adjust the manifold gas pressure see

the “GAS PRESSURE ADJUSTMENT” instructions

in the “CHECKING AND ADJUSTMENTS” section.

22. Replace the upper front jacket panel.

23. Check all safety switches for proper operation before

placing boiler on-line.

Required Gas Pressure

Provide gas supply pressure at inlet to boiler gas train

as follows:

LP

Nat

Minimum (in W.C.)

11

6

Maximum (in W.C.)

14

14

Measure pressure when the boiler is fi ring at full rate.

Low gas pressure could indicate undersized gas line or

insuffi cient gas supply.

Static and operating gas pressure required at the gas

valve inlet is between 6" W.C. and 14" W.C. for natural

gas and 11" W.C. and 14" W.C. for propane. If the gas

pressure is above this limit, a lock-up style regulator

suitable for dead end service such as an Equimeter or

Fisher must be installed to prevent increase (creep) of

gas pressure when the units are not operating. This

pressure regulator (supplied by others) may be installed

at the service entrance to each unit or a “master”

regulator sized to handle multiple units may be utilized.

Consult local gas utility or regulator manufacturer for

recommendations to meet specifi c job site requirements.