LCD INSTALLATION AND OPERATION INSTRUCTIONS

Page 22

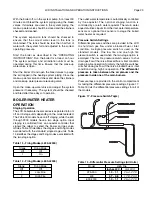

Table 12 - LCD Electrical Requirements

Recommended

LCD

Circuit Breaker

*Running

Model

(Amps) Amps

LB/LW 225-600

15

3.9

LB/LW 750

15

6.0

LB/LW

1050-1970

20

11.4

LB/LW

2300

20

14.4

*Use separate circuit breaker that is properly sized for

pump and pump contactor.

Line voltage fi eld wiring of any controls or other devices

must conform to the temperature limitation of type T wire

at

95°F

,

35°C

above room temperature. Use copper

conductors with a minimum size of #14 awg. Use

appropriate wiring materials for units installed outdoors.

The wire size must be compatible with the total amp

draw of the circuit.

Refer to the wiring diagram supplied with the boiler/

water heater for proper wiring connections.

GENERAL OPERATION

WARNING: Before proceeding read and fully

understand the instructions contained in this

manual. Do not attempt to operate this boiler/

water heater if it has not been installed in

accordance with the guidelines set forth in this

manual. Failure to comply with this warning can

result in extensive property damage, severe

personal injury or death!

Should overheating occur or the gas supply fail to shut

off, turn off the manual gas control valve to the

appliance. Do not interrupt water fl ow through the boiler/

water heater.

En cas de surchauffe ou si l'alimentation en gaz ne

s'arrête pas, fermez manuellement le robinet d'arrêt de

l'admission de gaz.

Hydronic Heating Boilers

Open the make-up water valve and slowly fi ll the boiler

and all of the radiation with water. Ensure that all bleed

and drain valves are closed.

Adjust the make-up water pressure regulator so a

minimum

12 psig

,

83 kPa

system pressure is

maintained at the highest point in the system piping. If

a make-up water pump is used adjust it to maintain a

minimum

12 psig

,

83 kPa

system pressure.

Open the system bleed and drain valves one at a time

to purge the air trapped in the heating system piping.

When applicable, provisions for vent, bleed and gas

relief lines must be made in accordance with the latest

revision of ANSI Z223.1/NFPA 54.

Safe lighting and other performance criteria were met

with the gas manifold and control assembly provided on

the boiler. All gas connections MUST be leak tested

before putting the boiler into operation.

WARNING: Never use an open fl ame to test for

gas leaks. Always use an approved leak

detection method. Failure to comply with this

warning can cause extensive property damage,

severe personal injury or death!

Whenever the gas supply piping is pressure tested the

boiler/water heater gas controls must be protected. If the

test pressure is equal to, or less than

1/2 psig

,

3.5 kPa

isolate the boiler/water heater by closing it's manual shut

off valve, see Figure 16. If the test pressure is greater

than, or equal to

1/2 psig,

3.5 kPa

, disconnect the

boiler/water heater and its individual shut-off valve.

ELECTRICAL WIRING

Electrical Power Connections

CAUTION:Label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper and dangerous operation! Verify proper

operation after servicing.

ATTENTION. Au moment de l'entretien des

commandes, étiquetez tous les fi ls avant de les

débrancher. Des erreurs de câblage peuvent

e n t r a î n e r u n fo n c t i o n n e m e n t i n a d é q u a t e t

dangereux. S'assurer que l'appareil fonctionne

adéquatement une fois l'entretirn terminé.

The electrical connections to this boiler/water heater

must be made in accordance with all applicable local

codes and the latest revision of the National Electrical

Code, ANSI/NFPA-70. Installation should also conform

with CSA C22.1 Canadian Electrical Code Part I if

installed in Canada.

Install a separate 120 volt 15 or 20 amp circuit breaker

for the boiler/water heater and pump, see Table 12.

A properly rated shut-off switch should be located at the

boiler/water heater. The boiler/water heater must be

grounded in accordance with the authority having

jurisdiction, or if none, the latest revision of the National

Electrical Code, ANSI/NFPA-70.