25

Cast Iron Condensing Boilers – Installation Manual

FlexCore Stainless Steel Condensing Boilers – Installation Manual

Figure 17 depicts the proper way to connect the boiler

to the gas supply piping. The manual shut-off valve

MUST be installed in the supply piping. It should be

installed

5 ft, 1 m above the floor where required by

local codes. Provide a sediment trap at the bottom of the

vertical section of the gas supply pipe upstream of the

gas controls.

A ground joint union should be installed between the

boiler gas controls and the supply piping. Each of these

items are needed to ensure long life and ease of

servicing. Always use a pipe sealant that is suitable for

use with with the type of gas (NG/LP) being used.

Table 8 - Gas Pipe Capacity

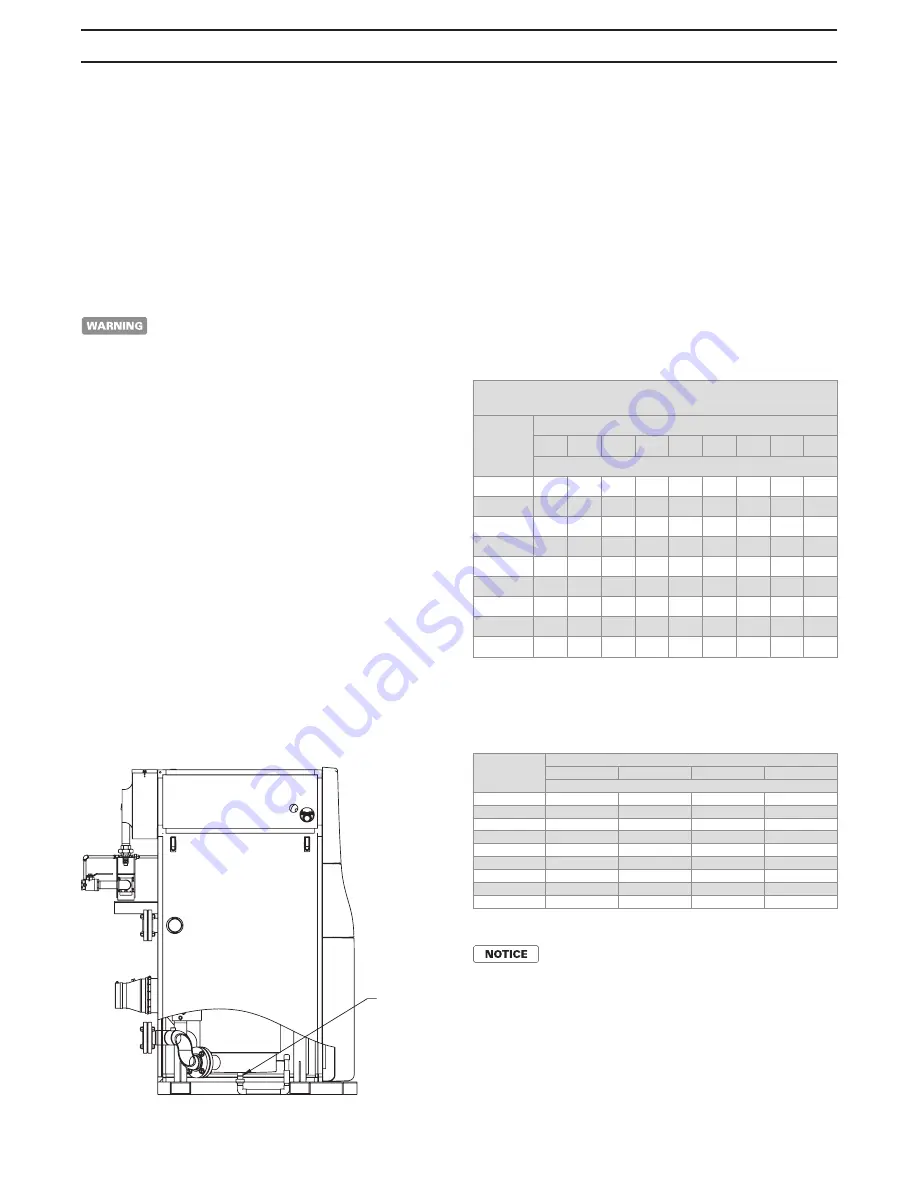

Figure 16 - FlexCore Series Condensate Drain

CONDENSATE PIPING

The condensate trap provided with the boiler must be

attached to the bottom pan and piped to a suitable floor

drain (consult local code) or condensate pump. If a

condensate neutralization device is required by local

code, it must be positioned prior to boiler room drain. Fill

the condensate trap with water, check and maintain water

level in trap during operation prior to start-up.

GAS SUPPLY PIPING

Check the boiler rating plate to make sure that

the boiler is for the type of gas that

will be used. If it isn’t, do not connect the

boiler to the gas supply. Failure to comply with

this warning can result in extensive property

damage, severe personal injury or death!

The FlexCore comes from the factory ready to be piped

to the gas supply. If for any reason the boiler is not for

the type of gas available at the installation site, call your

RBI representative to resolve the problem.

Table 8 should be used to ensure that the gas supply

piping is sized properly. If more than one appliance is

supplied by the same supply pipe, the piping must be

sized based on the maximum possible demand. Do not

neglect the pressure drop due to pipe fittings. Table 8

should be used in conjunction with Table 9 to ensure

that the gas supply piping has the capacity to meet the

demand.

Maximum pipe capacity in ft

3

/hr based on 0.60 specific gravity gas

at a pressure of 0.5 psig or less and a 0.3" WC pressure drop.

Nominal

Iron Pipe

Size

Pipe length in feet

10

20

30

40

50

60

80

100

150

Maximum gas volume of pipe (ft

3

/hr)

1"

520 350 285 245 215 195 170 150 120

1

1

/

4

"

1050 730 590 500 440 400 350

305

250

1

1

/

2

"

1600 1100 890 760 670 610 530

460

380

2"

3050 2100 1650 1450 1270 1150 990

870

710

2

1

/

2

"

4800 3300 2700 2300 2000 1850 1600 1400 1130

3"

8500 5900 4700 4100 3600 3250 2800 2500 2000

4"

17,500 12,000 9700 8300 7400 6800 5800 5100 4100

5"

31,700 21,800 17,500 15,000 31,300 12,000 10,300 9110 7320

6"

51,300 35,300 28,300 24,200 21,500 19,500 16,700 14,800 11,900

Note: Multiply the gas volume by 0.62 for propane flow capacity in

ft

3

/hr. Multiply the propane flow capacity by 2500 Btu/ft3 to determine

the propane Btu/hr capacity for a given pipe size and length.

Table 9 - Equivalent Pipe Length Chart

A lockup style regulator, supplied by others,

must be installed, see Figure 17, if gas

pressure exceeds (14 in WC). The regulator,

when installed as shown, must be installed

at a distance of at least 10 pipe diameters

from the boiler main gas valve. All boilers are

calibrated and factory test fired at

(7 in ± 1.0) WC.

Nominal

Iron Pipe

Size

Type of pipe fitting

90° Elbow

Tee

1

Gas Valve

2

Gas Cock

2

Equivalent pipe length, (ft)

1"

2.6

5.2

0.6

1.5

1

1

/

4

"

3.5

6.9

0.8

1.9

1

1

/

2

"

4.0

8.0

0.9

2.3

2"

5.2

10.3

1.2

3.0

2

1

/

2

"

6.2

12.3

1.4

3.5

3"

7.7

15.3

1.8

4.5

4"

10.1

20.2

2.4

6.0

5"

12.6

25.2

2.9

7.3

6"

15.2

30.4

3.5

13.4

Notes: 1. For flow through branch.

2. For flow at full open.

CONDENSATE

DRAIN

RIOM-0214_A