21

Set up and operation for DC PULSE TIG Welding Razor16O/2OO TIG-MMA

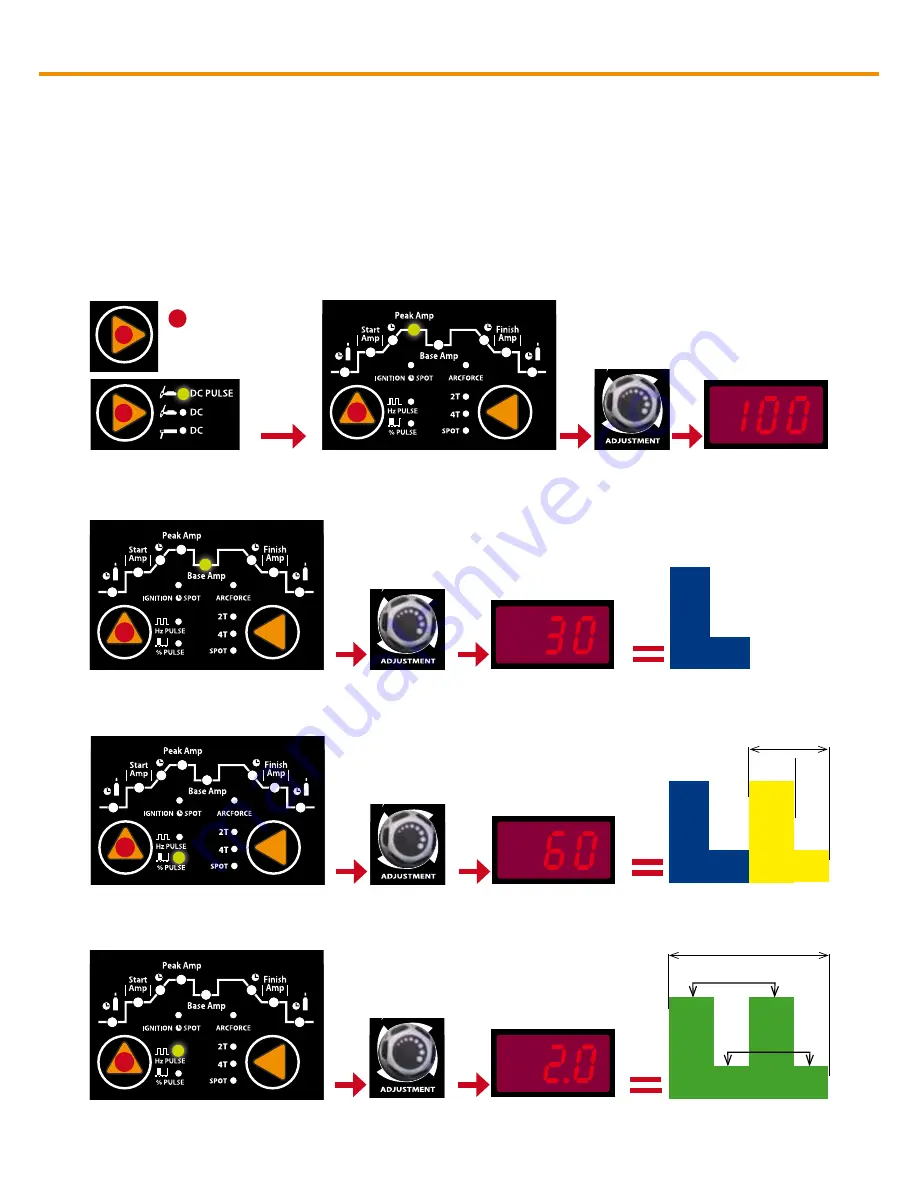

1. Select DC Pulse by pushing

selector button to cycle through to

illuminate DC Pulse icon.

Indicates Active

Selector Button

2. Select Peak Amp by pushing the selector

button to cycle through to illuminate the Peak

Amp Icon

3. Rotate the Adjustment Encoder Knob to set

the Peak Amp at 100A

(Range is 10-200 Amps)

4. Select the Base Amp by pushing the

selector button to cycle through to illuminate

the Base Amp Icon

5. Rotate the Adjustment Encoder Knob to set

the Base Amp at 30A - (Range is 10-200 Amps)

100A

30A

Peak

Amp

Base

Amp

7. Rotate the Adjustment Encoder Knob to set the

Pulse Width at 60% - (Range is 10 - 90%).

6. Select the Pulse Width (on time of the

Peak Amp) by pushing the selector button to

cycle through to illuminate the % Pulse Icon

100A

30A

Peak

Amp

Base

Amp

100A

60%

30A

40%

Peak Amp

On Time

Pulse Width

8. Select the Pulse Frequency by pushing the

selector button to cycle through to illuminate

the Hz Pulse Icon

9. Rotate the Adjustment Encoder Knob to set the

Pulse Frequency to 2 Hz - (0.5 - 200Hz)

Peak

Amp

Base

Amp

100A

60%

30A

40%

100A

60%

30A

40%

The Razorweld TIG machine has digital pulse frequency control. All the parameters for DC Pulse Tig

welding - Peak Amp, Base Amp, Pulse Frequency and Pulse Width are easy to set via the digital control

panel.

EXAMPLE OF PULSE DC TIG WELDING - SETUP PARAMETERS:

Material = Stainless Steel x 5/64 / Tungsten Electrode = 1/16 2% Thoriated / Gas = Argon

The following steps are a guide as a starting point for you to set the machine up in Pulse mode to give an

example of welding in Pulse mode function. You can experiment by changing any of the variables to see

what effect it has over the welding and what the end result can be, but it is suggested to change only one

variable at a time and then check the welding to see what the result is, in this way you acquire a better un-

derstanding of how each variable affects the welding current.

Time = 1 Second (Hz)

Summary of Contents for KUMJRRW160

Page 35: ...NOTES ...