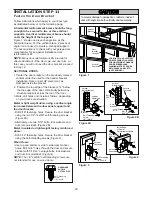

Motor Unit Assembly Parts

34

2

12

10

15

4

3

DN

UP

Brown

Wire

(Down)

Contact

LIMIT SWITCH ASSY.

Grey

Wire

Yellow

Wire

(Up)

Contact

Center Limit

Contact

Drive

Gear

11

5

6

7

9

8

9

8

20

14

13

16

1

3

18 19

17

5

KEY

PART

NO.

NO.

DESCRIPTION

1

41A4371

Belt cap retainer

2

41A4885-2

Gear and sprocket assy.,

Complete with: Spring washer;

Thrust washer; Retaining ring;

Bearing plate; Roll pins (2); Drive

gear and worm gear; Helical gear

w/retainer and grease

3

41A2817

Drive/worm gear kit w/grease,

Roll pins (2)

4

41B4245

Line cord

5

41C4876

Wire harness assembly with plug

6

41A5021-F

Receiver logic board assembly

Complete with Logic board

7

41A4888

End panel w/all labels

8

4A1344

Light socket

9

108D34

Lens

10

30B363

Capacitor – 1/2 h.p.

11

12A373

Capacitor bracket

KEY

PART

NO.

NO.

DESCRIPTION

12

41D3150

Terminal block w/screws

13

41C4842

Universal replacement motor &

bracket assembly, Complete

with: Motor, worm, bracket,

bearing assembly, RPM sensor.

14

41AD0369-2

Cover

15

41A2818

Helical gear & retainer w/grease

16

41D3452

Limit switch assembly

17

41C4398A

RPM sensor assembly

18

41A2826-1

Shaft bearing kit

19

41A2822A

Interrupter cup assembly

20

41A4889

End panel

NOT SHOWN

41A2825

Opener assembly hardware kit

(includes screws not designated

by a number in illustration)