Wuhan Raycus Fiber Laser Technologies Co., Ltd

User Guide RFL-QCW150/1500

6

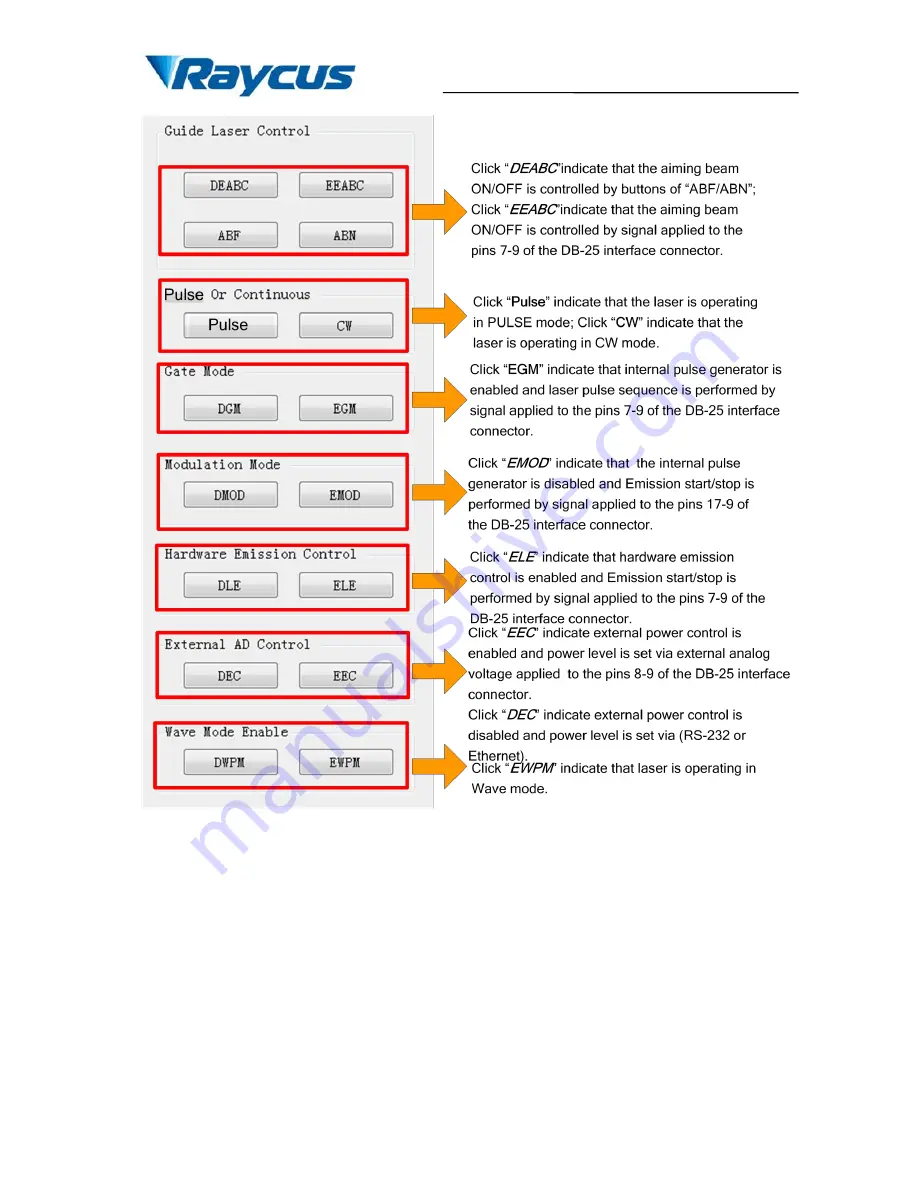

Figure 10 Control Mode Setting

Note

:

Steps of laser emission start:

Step 1: Enable emission control

(Enable emission control is performed by signal applied to the pins 7-9 of the DB-25 interface

connector if hardware emission control is enabled (ELE), while it is performed by command via

RS-232 or Ethernet if hardware emission control is disabled (DLE).)

Step 2: Emission starts/stops