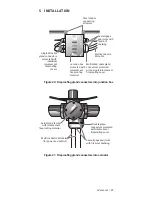

Connect the MI cable to junction boxes, motors, or other

equipment suitable for the area classification (hazardous

or nonhazardous) and environmental conditions

(corrosive, wet, etc.) expected. Metal junction boxes are

recommended because the cable sheath can be bonded to

ground, through the gland connector, to the junction box.

If using nonmetallic junction boxes, the gland connector

must be connected to a ground bushing (Figure 14) to

ensure that the cable sheath is bonded to ground.

Figure 14: Typical ground bushing (for nonmetallic

enclosures only)

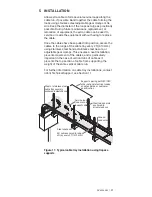

Install the “pot” so that it extends above the bottom of the

junction box (Figures 15 and 16) to prevent moisture, due

to condensation, from contaminating the face of the pot.

Screw the gland connector into the junction box hub and

tighten the compression nut (rear nut on gland connector)

to the torque value shown on the tag supplied with the

factory terminated cable or field termination kit. This

ensures that the cable sheath is properly bonded to ground

and provides a proper flame path in hazardous areas.

Note: Minimize handling the tails to avoid breakage.

5 INSTALLATION

24 | nVent.com

Summary of Contents for pyrotenax Alloy 825

Page 1: ...MI Cable Industrial Wiring Installation Manual For Alloy 825 Sheath Cables ...

Page 4: ...iv nVent com ...

Page 46: ...42 nVent com ...

Page 47: ...nVent com 43 ...