the Rapid Rise Fire Tests of Protection Materials for

Structural Steel. The support system component material

should be selected based on the environment in which

it is installed, as it may have to withstand the high

temperatures possible in a hydrocarbon flash fire and / or

the harmful effects of corrosive areas. Ensure that the

materials used to support the cables are compatible with

the cable sheath.

Note: For fire-rated installations, do not use material

such as aluminum, brass, copper, plastic, lead, wood, etc.,

since these materials will fail quickly during a fire.

The support system must provide strength and working

load capabilities to meet the load requirement of the

wiring system. Support the cables on horizontal and

vertical runs at the spacing requirements in the NEC / CEC,

other national electrical codes and standards, or per

customer’s specifications. Pay special attention to fire-

rated installations as it may be necessary to use support

spacing closer than that specified in the NEC / CEC or

other national electrical codes and standards.

Several support methods may be used; however, cable tray

is recommended due to its wide availability and familiarity

among installing contractors.

Cable Tray

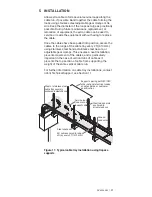

Figures 11 and 12 show two typical cable tray installation

methods using open ladder, trough-type tray. In Figure 11,

the cable tray is supported using a rod and channel trapeze

type system. In Figure 12, the tray is supported using steel

I-beams. Follow the cable tray manufacturer’s installation

instructions to install the tray.

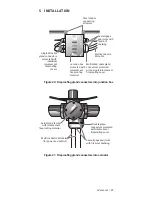

Complete the cable tray installation before installing the

MI cables. Metallic cable tray systems must be electrically

continuous and effectively bonded as per the requirements

of the NEC / CEC or other national electrical codes and

standards.

Install cables so that the sheaths are in good electrical

contact with the tray. Do not overload the cable tray; follow

the loading requirements in the NEC / CEC or other national

electrical codes and standards when installing cables in

cable tray. Refer to pages 18 and 19 for details regarding

the installation of single and multiconductor MI industrial

wiring cables.

5 INSTALLATION

20 | nVent.com

Summary of Contents for pyrotenax Alloy 825

Page 1: ...MI Cable Industrial Wiring Installation Manual For Alloy 825 Sheath Cables ...

Page 4: ...iv nVent com ...

Page 46: ...42 nVent com ...

Page 47: ...nVent com 43 ...