39

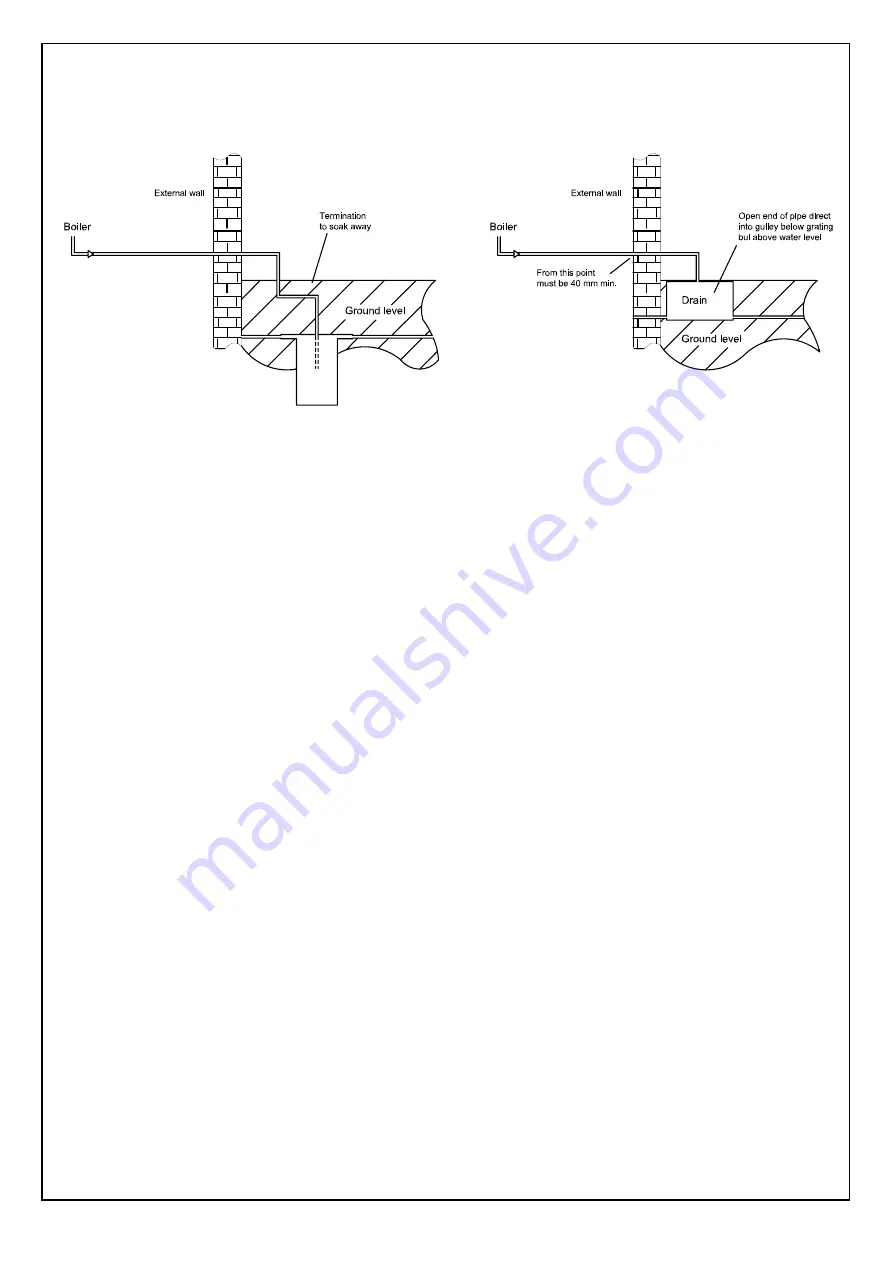

3 - TERMINATION TO SOAK AWAY 4 - TERMINATION TO DRAIN / GULLY

5.27

CONVERTING THE APPLIANCE

TO DIFFERENT GAS TYPES

Boilers are factory set to work for use

with Natural gas or LPG gas. This is

clearly marked on the packaging and

boiler data badge.

To convert a boiler from one gas to

another this operation must be carried

out by a qualified competent person,

with all necessary equipment

authorised by th

authorised by the manufacturer.

It will also be necessary to obtain a data badge

conversion kit directly from The White Boiler

Company.

1 - Remove the case.

2 - Check gas mains pressure at the gas

valve test nipple upstream (fig.35)

with boiler operating (sect.6.8).

3 - Adjust fan speed as sect.3

(technical data).

4 - Measure the level of CO2 as in section

as in section

6.9 and table 10, and adjust to correct

6.9 and table 10, and adjust to correct

data settings information.

data settings information.

5 - Affix new data badge.

6 - Replace in reverse order.

5.28 ELECTRICAL

CONNECTIONS

IMPORTANT:

Electricity supply must be as specified in

clause (sect. 4.22).

- When controls external to the appliance are

required, design of the external electrical

circuits should be undertaken by a

competent person. In accordance with the

IEE wiring regulations.

It is essential that all external controls

are VOLT FREE.

Factory fitted internal wiring must not be

disturbed when wiring external controls.

- To gain access to the electrical box remove

the front panel of the case as described in

clauses sect. 8.2.

8.2.

You can slide towards the top the

You can slide towards the top the

instrument panel box and push the retaining

instrument panel box and push the retaining

latches and remove the instrument panel

latches and remove the instrument panel

(sect. 8.24).

(sect. 8.24).

- Heat resistant flexible cable is fitted

- Heat resistant flexible cable is fitted

between the isolator and the terminal block

between the isolator and the terminal block

which is a 3 core cable

which is a 3 core cable of 0.75 mm

2

(24x0,2

mm) to BS 6500.

Make sure all wires to the appliance are

routed away from sharp edges and hot

surfaces.

The cable must be fastened with its cord

anchorage and connected so that should

the cable slip from the anchorage the

current carrying conductors become taut

before the earthing conductor. Securely

tighten all terminal screws and arrange

the cable with slack between the cord

anchorage and the terminal block.

WARNING:

If the supply cord is damaged, it must be

replaced by a service engineer (supply

cord available from The White Boiler

Company).

5.29 OUTDOOR SENSOR

For use, consult Outdoor Sensor

instructions.

Fig. 33

Fig. 34

Summary of Contents for White Boiler WH 80

Page 2: ...2 ...

Page 21: ...21 4 10 FLUE TERMINAL POSITION ...

Page 54: ...10 ELECTRICAL SYSTEM DIAGRAM 54 Fig 61 ...

Page 55: ...55 11 SPARE PARTS Fig 62 ...

Page 59: ......

Page 62: ...61 ...

Page 63: ...62 ...

Page 65: ...64 FLOWCHART FOR CO LEVEL AND COMBUSTION RATIO CHECK ON COMMISSIONING A CONDENSING BOILER ...

Page 66: ...65 12 1 ANALYSER CHECK LIST ...