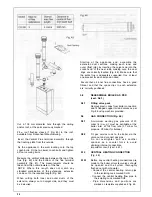

Cut a 105 mm diameter hole through the ceiling

and/or roof, at the point previously marked.

Fit a roof flashing sleeve (7 Fig. 43) to the roof,

available from Ravenheat Manufacturing.

Insert the-Vertical Flue terminal assembly through

the flashing plate from the outside.

Fix the appliance to the wall, locating onto the top

coach bolts. Fit the two lower coach bolts and tighten

all four securing bolts.

Measure the vertical distance between the top of the

flue (Fig. 42) and the bottom of the flue terminal

assembly (Fig. 41). The measurements should be

taken from the outer diameter of the flue.

NOTE: Where this length does not match any

standard combination of the extensions, extension

can be cut to the required length (Fig. 44).

When cutting both inner and outer ducts of the

extension, always cut on spigot side, and they must

be de-burred.

Starting at the appliance end, assemble the

extension duct sections, making each inner and

outer (flue) joint by inserting the spigot end into the

socket end of the next tube, making sure the seal

rings are correctly located (Fig. 44). Make sure that

the entire flue is adequately supported. Use at least

one bracket for each extension used.

Ensure that all inner flue connections have a good.

fit/seal, and that the space clips in each extension

are correctly positioned

5.8

5.8.1

5.9

5.9.1

5.9.2

5.10

5.10.1

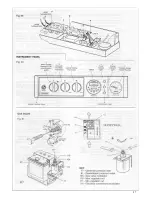

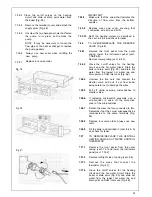

REASSEMBLE BOILER AS PER

(sect. 5.6.1)

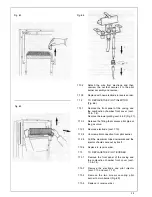

Fitting valve pack

Remove plastic caps from boiler connection

and fit flanged copper tail and valves as per

Fig. 46 using washers provided.

GAS CONNECTION (Fig. 46)

A minimum working gas pressure of 20

mbar (8 in w.g.) must be available at the

boiler inlet at full flow rate (37 mbar for

propane, 29 mbar for butane).

Fit gas service cock to the boiler via the

union nut and connect gas pipe.

Do not overtighten and use another

spanner as a counter force to avoid

straining internal connections.

Important consult (sect 4.5.1).

CENTRAL HEATING CONNECTION

(Fig. 46)

Before any central heating connections are

made to the boiler all system valves should

be opened and the system thoroughly

flushed out with cold water.

- Connect the central heating return pipe

to the isolating cock marked CHR.

- Connect the central heating flow pipe to

the isolating cock marked CHF.

- Pipe dimensions and positions are

marked on template supplied and fig. 45.

24

Summary of Contents for CSI 85

Page 26: ...27...

Page 42: ......

Page 45: ...SECTION 9 ELECTRICAL SYSTEM DIAGRAM Fig 94 46...

Page 46: ...47...

Page 47: ......

Page 48: ...49...

Page 52: ......

Page 55: ...Chartists Way Morley Leeds LS27 9ET Telephone 0113 252 7007 Tfax 0113 238 0229...