Manual No. 016-0159-925 Rev. F

49

Data Menu

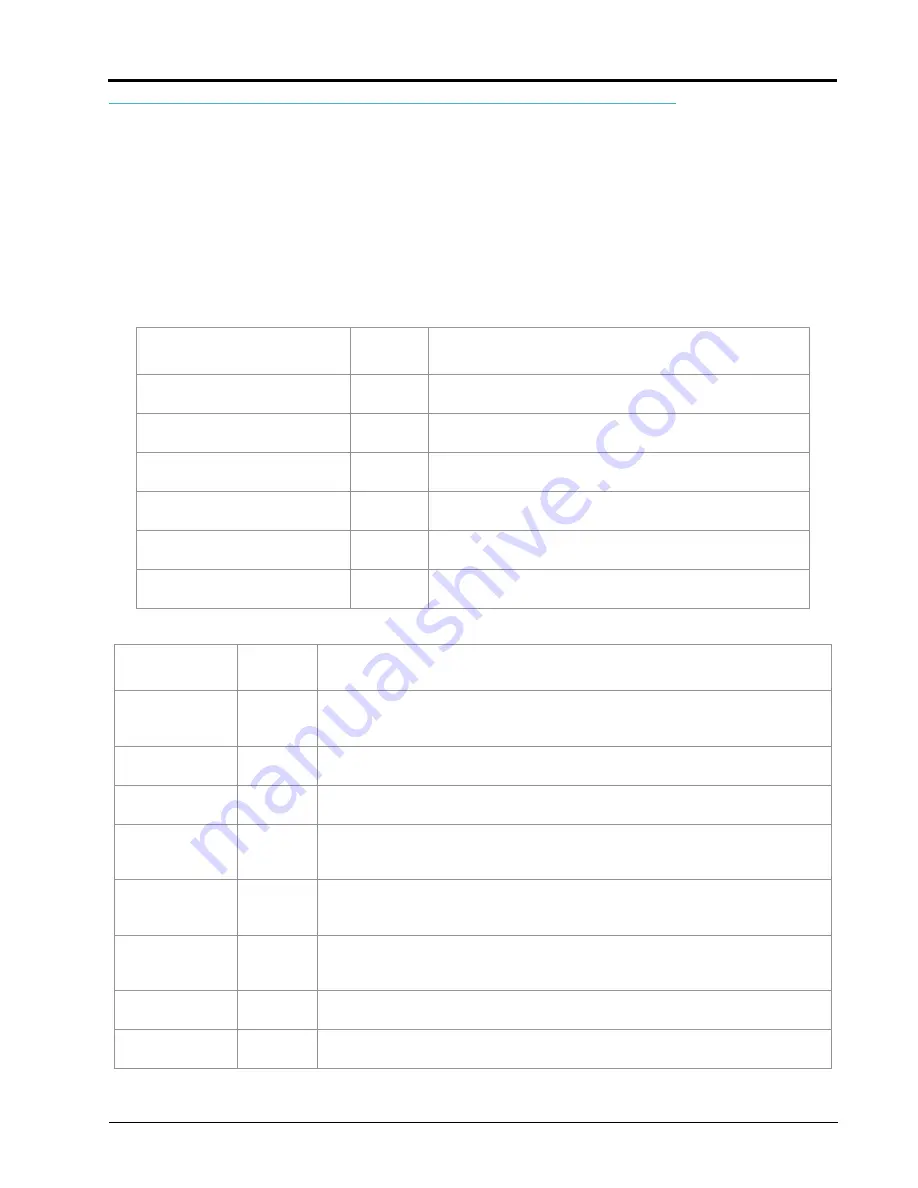

SCS Alarm Definitions

The following are brief descriptions of the visual and audible alarms for the SCS console. The audible alarm

may be enabled or disabled from the Console submenu within the Data Menu.

Note:

The Audible Alarm:

1.

Beeps for 1/2 second once per second.

2.

Beeps for 1/4 second twice per second.

3.

Continuous.

4.

Beeps for 2 seconds every 16 seconds.

Data Display

Audible

Alarm (*)

Alarm Description

CHECK CAN NODES OR CAN

COMMUNICATIONS

4

Console is not communicating with CAN nodes (See Chapter

9,

CHECK CONTROL NODE #

4

Console is not communicating with product control node #

(See Chapter 9,

).

CHECK ACCUBOOM NODE

4

Console is not communicating with AccuBoom control node

(See Chapter 9,

).

CHECK AUTOBOOM NODE

4

Console is not communicating with AutoBoom control node

(See Chapter 9,

).

CHECK BOOM SENSE NODE

4

Console is not communicating with boom sense/speed node

(See Chapter 9,

).

CHECK ROW SENSE NODE

4

Console is not communicating with row sense node (See

Chapter 9,

).

Mode Display

Audible

Alarm (*)

Alarm Description

VAR RATE

1

When Variable Rate Change alarm is enabled, visual and audible alarms will occur

for 4 seconds to indicate that a valid rate change string has changed the target rate.

Function acts independent of audible alarm setting.

BIN LEVL

1

When Bin Level Alarm (Granular mode only) is enabled, alarm occurs to indicate low

bin level (See

VAC ERR

1

When Vacuum Alarm (liquid chemical injection mode only) is enabled, alarm occurs

to indicate a vacuum error (See

FLOW SW

1

When Flow Switch Monitor Alarm (liquid chemical injection mode only) is enabled,

alarm occurs to indicate out of tolerance difference between flow switch monitor and

flow reading (See

LOW LIM

2

When a Low Flow Rate Limit is entered, alarm occurs to indicate that volume/minute

has dropped below low limit (automatic mode only). (See

page 41).

DUAL FLOW

2

When programmed in Gran 3, Dual Flow Alarm will occur when difference between

dual encoder readings becomes out of tolerance (See

OFF RATE

3

Alarm occurs when volume/area rate is out of tolerance from the target application

rate for more than 5 seconds (See

LOW LEVL

4

When a Low Tank value is entered, alarm will occur when volume/tank is less than

Low Tank limit (See