Maintenance and service

12

126

4.

Loosen the screw [8] again by approx. one half turn to guarantee easy adjust-

ment of the extension vane position.

The screw may only be loosened so that the extension vane position

can be adjusted and the extension vane is still fastened tightly to the

main vane.

5.

Click the flat spring back into place with the adjustment lever.

6.

If necessary, repeat the work stages with other extension vanes which must

be replaced.

Reattach both spreading discs. See

12.8.2: Mounting the spreading

2.

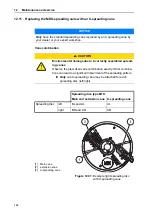

Attach the spreading vane

to the spreading disc using

the new screw [8], the new

securing nuts [6] and the

new washers [7].

Figure 12.20:

Spreading vane fastening

points

3.

Tighten the screw so that

this lies flat and tight (tight-

ening torque: approx.

8

Nm

).

Figure 12.21:

Spreading vane fastening

points

8

7

7

6

Summary of Contents for MDS 14.2

Page 8: ...Intended use 1 2...

Page 28: ...Safety 3 22...

Page 38: ...Technical data 4 32...

Page 42: ...Axle load calculation 5 36...

Page 44: ...Transportation without tractor 6 38...

Page 86: ...Machine settings 8 80...

Page 96: ...Calibration and discharging residual material 9 90...

Page 110: ...Important information on spreading 10 104...

Page 114: ...Faults and possible causes 11 108...

Page 146: ......