en-4

2 INTRODUCTION

2.3UIDELINES FOR THE DISPOSAL OF SCRAP PRODUCTS ______________________

2.3.1 DURING SERVICE LIFE _______________________________________________

Used oil, oil filters and engine coolant are hazardous materials. Recommended procedures must be followed for their

safe removal.

If a fluid leaks, contain the spill to make sure that the leak does not flow into the ground or drainage system. Follow the

local laws to make sure that leaks are controlled safely.

The maintenance procedures in this manual make sure that the damage that the machine can cause in the local

environment is controlled safely.

When the machine completes its full service life, the following actions must be taken.

2.3.2

END OF SERVICE LIFE _______________________________________________

These guidelines must be used with applicable Health, Safety and Environmental laws. Always use the approved local

waste disposal and agencies for recycled materials.

•

Park the machine in a location to use all of the necessary lifting equipment.

•

Use correct tools and Personal Protective Equipment (PPE) and take instruction from the technical

manuals applicable to the machine.

•

Remove and store correctly

1. Batteries

2.

F

uel

3. Engine coolant

4. Oils

•

Disassemble the structure of the machine and refer to the technical manuals where applicable. Give

attention to parts that have mechanical pressure or tension applied to the part in the machine, including

springs.

•

Items that continue to have a service life must be separated and returned to the local store.

•

Items that are worn must be separated into the material groups and removed according to the agencies

for recycled materials that are available. Common types are as follows:

• Steel

• Non ferrous metals

• Aluminium

• Brass

• Copper

• Plastic materials

• Identified

• Can be recycled

• Can not be recycled

• Not identified

• Rubber

• Electrical and Electronic Components

•

If an item is not easily separated into different material groups, the material must be added to the

“General discarded materials” area.

•

Do not burn discarded materials.

Change the machinery records to show that the machine is not in service and is discarded. Supply this serial number to

Ransomes Jacobsen Warranty Department to close their records.

Summary of Contents for Matador 71

Page 9: ...en 7 INTRODUCTION 2 NOTES...

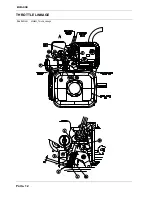

Page 10: ...Parts 8 MATADOR Illustration Engine Group 4300619_Group_Engine_71cm...

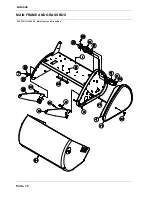

Page 12: ...MATADOR Illustration Parts 10 MAIN FRAME AND GRASS BOX 4299911_Main Frame and Grass Box...

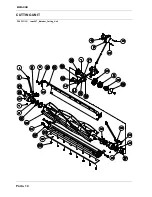

Page 14: ...Parts 12 MATADOR Illustration THROTTLE LINKAGE 4299991_Throttle_Linkage...

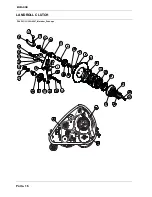

Page 16: ...Parts 14 MATADOR Illustration a b c CUTTING UNIT lmac067_Matador_Cutting_Unit...

Page 18: ...Parts 16 MATADOR Illustration LANDROLL CLUTCH 302r0007_Matador_Drive eps...

Page 20: ...Parts 18 MATADOR Illustration HANDLES AND CONTROLS 4299912_Handles_Matador_71cm...

Page 24: ...Parts 22 MATADOR Illustration FRONT ROLL 302r0005_Matador_Front_Roll eps...

Page 26: ...Parts 24 MATADOR Illustration LANDROLL 302r0006 2_Matador_Landroll eps...

Page 30: ...Parts 28 MATADOR Illustration MATADOR TOW BAR 71cm TRAILING SEAT LMAA628_Matador_Seat eps...

Page 32: ...Parts 30 MATADOR Illustration LANDROLL RUBBER COVERED 302R0006_rubber coated eps...