Vector Solo 65kV Applicator - Maintenance

22

AH-08-02.6

DO NOT

allow the fluid lines to stand

empty without flushing first! This will cause

dried paint flaking and clogging of the fluid

lines, applicator passages, and/or nozzles.

C A U T I O N

!

All repairs should be made on a clean, flat sur-

face. If a vise is used to hold parts during service

or repair, DO NOT clamp onto plastic parts and

always pad the vise jaws!

The following parts should be thoroughly packed

with dielectric grease (LSCH0009-00) leaving

NO

air space or voids when assembling:

• All O-Rings (PTFE o-rings do not need

lubrication)

• Needle Shaft Assembly

• Packing Tube

• Cascade and Barrel

Equipment Required

• Special Multi-Purpose Wrench (79854-00) *

• 4mm, 3mm, and 2.5mm Allen Wrenches *

• Screwdriver (blade)

• Jam Nut Removal Tool (79793-00) *

• Dielectric Grease (LSCH0009-00) *

• Sealant, Medium Strength (7969-10)

• Dowel, 6mm (1/4") diameter

Note: * Supplied with applicator

APPLICATOR REPAIR

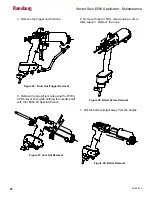

Figure 15: kV Probe

There is a 10 giga ohm resistor in the

probe that lowers the output voltage. The

maximum kV rating is at no load. Paint

overspray and other contaminates on the

barrel will lower the kV probe reading.

NOTE

4. Using the meter set to kV, measure the output

voltage of the applicator. Voltage output reading

is between 52 and 60kV.

5. See "Troubleshooting" in the "Maintenance"

section for possible cause of poor performance.

1 - Full Voltage Setting

2 - 76634-00 Meter

3 - 76667-00 kV Probe

Ransburg