37

WARNING SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity and gas before servicing. Check appliance is safe when you have finished.

6. To

Remove

Clock

Disconnect from electricity supply.

Remove the Control Panel (See 1). Pull off the timer

control buttons.

Remove the timer/mounting bracket assembly from the

control panel by removing the fi xing screws.

Remove the timer from its mounting bracket by

depressing the plastic lugs on the timer case, at the same

time pulling the unit forward.

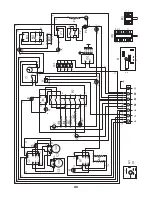

Reassemble in reverse order. When replacing leads refer

to the wiring diagram. Check operation of timer.

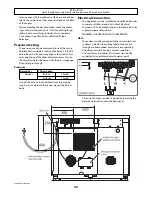

7. To Remove an oven Thermostat

Disconnect from the electricity supply.

Remove control panel and hotplate (see 1 & 2). Open

oven door. Remove oven furniture and slide out oven

roof liner if fi tted. Pull cooker forward to gain access

to the cover box at the rear of the cooker. Remove

the screws securing the cover and lift clear. The oven

thermostat capillary is clamped to the oven back sheet

with an earthing plate. Remove the screws and plate.

thermostat capillary

earthing plate

Left Hand Main oven

Remove the two screws holding the thermostat phial to

the oven fan cover at the rear of the oven.

Right hand Main oven and Slow Cook oven

Remove thermostat phial cover (2 screws). Unclip the

thermostat phial from the clips on the oven back.

Slow cook oven thermostat phial cover.

Feed the thermostat capillary out of the oven.

Disconnect wiring from thermostat. Remove 2 screws

holding thermostat to mounting panel. Fit new

thermostat and reassemble in reverse order. Ensure

that the phial is clipped to the oven back with the phial

centrally positioned between the clips.

Remember to refi t the earthing plate.

Check operation of thermostat.

8. To Change the Grill or Ceramic hob Controller

Disconnect from the electricity supply.

Remove the control panel and hotplate (see 1 & 2).

Disconnect wiring from controller. Remove 2 screws

holding controller to mounting panel. Fit new controller

and reassemble in reverse order. Check for correct

operation.

BEFORE SERVICING ANY GAS CARRYING COMPONENTS

TURN OFF GAS SUPPLY.

9. To

Change

Hotplate

Taps

Disconnect from the electricity supply.

Remove the control panel and hotplate (see 1 & 2).

Unplug the FSD lead from the rear of the tap. Undo

compression fi tting at the rear of the tap. Remove the

fi xings that secure the tap to the gas rail. Disconnect the

ignition switch wiring.

Remove the tap. Remove and discard the gasket seal.

Fit new gasket seal to replacement tap. Re-assemble in

reverse order. Check the appliance is gas sound. Check

hotplate ignition.

10. To Change Hotplate Burner Injector

Remove burner cap and head. Remove old jet. Fit new

injector. Reassemble in reverse order. Check appliance is

gas sound.

11. To Change Hotplate Burner Electrode

Lift off pan supports, remove burner cap. Remove the

screw holding the electrode. Pull electrode vertically

up suffi

ciently to grip the lead between thumb and

forefi nger. Pull off the electrode, but keep hold of the

lead. Fit new electrode to the lead. Fix electrode in

burner with screw. Replace burner cap. Check the burner

ignition. Replace pan supports.

12 To Remove or Change a Hotplate Burner.

Remove the hotplate tray (see 2).

The burners except the right hand wok burner

are mounted on support struts. For these burners,

disconnect the burner feed pipes at the burner. Remove

the screws at the front and rear holding the support

struts. Lift the strut and burners clear. The burners are

fi xed to the support struts with 2 screws. Remove the

appropriate burner and fi t the new one. Reassemble in

reverse order. Check burner operation is satisfactory.

RH Wok burner

Disconnect the burner feed pipes at the burner. Fit the

new one and reassemble in reverse order. Check burner

operation is satisfactory.

Summary of Contents for Excel FSD

Page 1: ...Excel FSD 110 Dual Fuel Users Guide Installation Service Instructions U109010 02...

Page 43: ...43...

Page 44: ...220506...