27

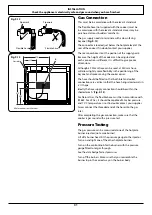

INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

Location of Cooker

The cooker may be installed in a kitchen/kitchen diner but

NOT in a room containing a bath or shower.

This appliance is designed for domestic cooking only. Use

for any other purpose could invalidate any warranty or

liability claim.

Note:

An appliance for use on LPG must not be installed

in a room or internal space below ground level, e.g. in a

basement.

Conversion

This appliance is supplied set for G20 20 mbar Cat II2H3+.

A conversion kit for another gas is available for the cooker.

If the appliance is to be converted to another gas we

recommend that this is carried out before installation.

n

We recommend an overpressure shut-off device or

pressure relief valve be used in any LPG installation

to prevent exposure of downstream fittings /

appliances to excessive pressure (over 75mbar) in

event of regulator failure.

After converting the appliance, please attach the Gas

Conversion sticker over the appropriate area of the data

badge – this will identify the gas type for which the appliance

is now set.

You will need the following equipment to complete the

cooker installation satisfactorily:

•

Stability bracket: If the cooker is to be supplied with gas

through a flexible hose, a stability bracket or chain must

be fitted.

These are not supplied with the cooker but

are available at most builders’ merchants.

•

Gas pressure tester/manometer.

•

Flexible gas hose: Must be in accordance with the

relevant standards.

•

Multimeter: For electrical checks.

You will also need the following tools:

1.

Electric drill

2.

Masonry drill bit (only required if fitting the cooker on a

stone or concrete floor)

3.

Wall plugs (only required if fitting the cooker on a stone

or concrete floor)

4.

Steel tape measure

5.

Cross head screwdriver

6.

Flat head screwdriver

7.

Spirit level

8.

Pencil

9.

Adjustable spanner

10.

Screws for fitting stability bracket

11.

13 mm spanner or socket wrench

Checking the parts:

3 pan supports

Wok cradle (Supplied)

ArtNo.110-0002 110 pan supports

ArtNo.000-0009 Wok ring, cast

Teppanyaki (Supplied)

Griddle (Optional)

ArtNo.311-0043 - Griddle 09

Grill pan and trivet

1x set of Telescopic runners

2 Flat shelves

Tall oven shelves & shelf supports

ArtNo.000-0010 Tall oven shelves

Plinth

Stability location bracket

ArtNo.350-0009 - 90

Classic DL plinth

Summary of Contents for EDL100DFF

Page 1: ...Encore Deluxe 100 Dual Fuel U111217 02 USER GUIDE INSTALLATION INSTRUCTIONS...

Page 4: ...ii...

Page 41: ...37 NOTE...

Page 42: ...38 NOTE...

Page 43: ...39 NOTE...

Page 44: ......

Page 45: ......

Page 46: ......