6

T E C H N I C A L I N F O R M AT I O N F O R

THE INSTALLER

This appliance shall be installed in

accordance with the regulations in force and

only in a well-ventilated space. Read the

instructions before installing or using this

appliance.

In the UK the regulations and standards are

as follows: -

In your own interest and that of safety, it is

law that all gas appliances be installed by

competent persons. CORGI registered

installers undertake to work to safe and

satisfactory standards. Failure to install the

appliance correctly could invalidate any

warranty or liability claims and lead to

prosecution.

3) INSTALLING THE HOTPLATE

Check that the appliance is in a good condition

after having removed the packaging. In case of

doubt, do not use the appliance and contact

qualified personnel.

Never leave the packaging materials

(cardboard, bags, polystyrene foam, nails,

etc.) within children's reach since they could

become potential sources of danger.

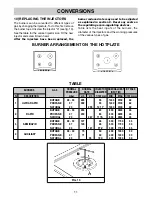

The size of the opening required in the top of the

cabinet is shown in fig. 7 and the accompanying

table. Always comply with the installation

dimensions (see fig. 7 – 8).

The appliance is class 3 and should therefore

installed built-in as detailed in these

instructions.

4) FIXING THE HOTPLATE

The hotplate has a special seal that prevents

liquid from infiltrating into the cabinet. Carefully

follow these instructions in order to correctly

apply this seal:

- Detach the seals from their backing, checking

that the transparent protection still adheres to the

seal itself.

- Turn the hotplate over and correctly position seal

"E" (fig. 9) under the edge of the hotplate itself, so

that the outer side of the seal perfectly matches

the outer edge of the hotplate. The ends of the

strips must fit together without overlapping.

- Evenly and securely fix the seal to the hotplate,

pressing it in place with the fingers.

- Fix the hotplate to the worktop with the brackets

“S”. Ensure the tag fits into the hole “H” on the

hotplate base, then tighten the screw “F” until it is

locked to the worktop (fig. 10).

- Above hotplate level the sidewalls (left or right)

must not be closer than the minimum dimensions

show in the fig. and table.

INSTALLATION

FIG. 7

FIG. 8

FIG. 9

FIG. 10

A

B

C

D

E

Four burner hotplate

553

473 67.5

59.5 100 min.

Five burner hotplate

553

473 67.5

59.5 175 min.

COMPLY WITH THE DIMENSIONS

(mm)

Summary of Contents for 58580

Page 16: ...16 V I...