10

11

TROUBLESHOOTING

TROUBLESHOOTING

TOOL OPERATING INSTRUCTIONS

TOOL OPERATING INSTRUCTIONS

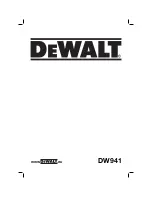

2. Insert the power load.

With the tool in the closed position

insert a power load strip into the cavity

in the base of the rubber handle and

push in until the flat of your finger tip is

firmly against the handle recess. The

first power load is now aligned with the

chamber.

Note:

Always use the lowest strength

power load and lowest power setting first,

for a firing test, then adjust the power to

suit the job.

3. Fire the tool.

Press the fastener guide firmly against

the work surface, and pull the trigger

4. Check the fastener has been correctly

set.

(See Fastening Applications, page 8)

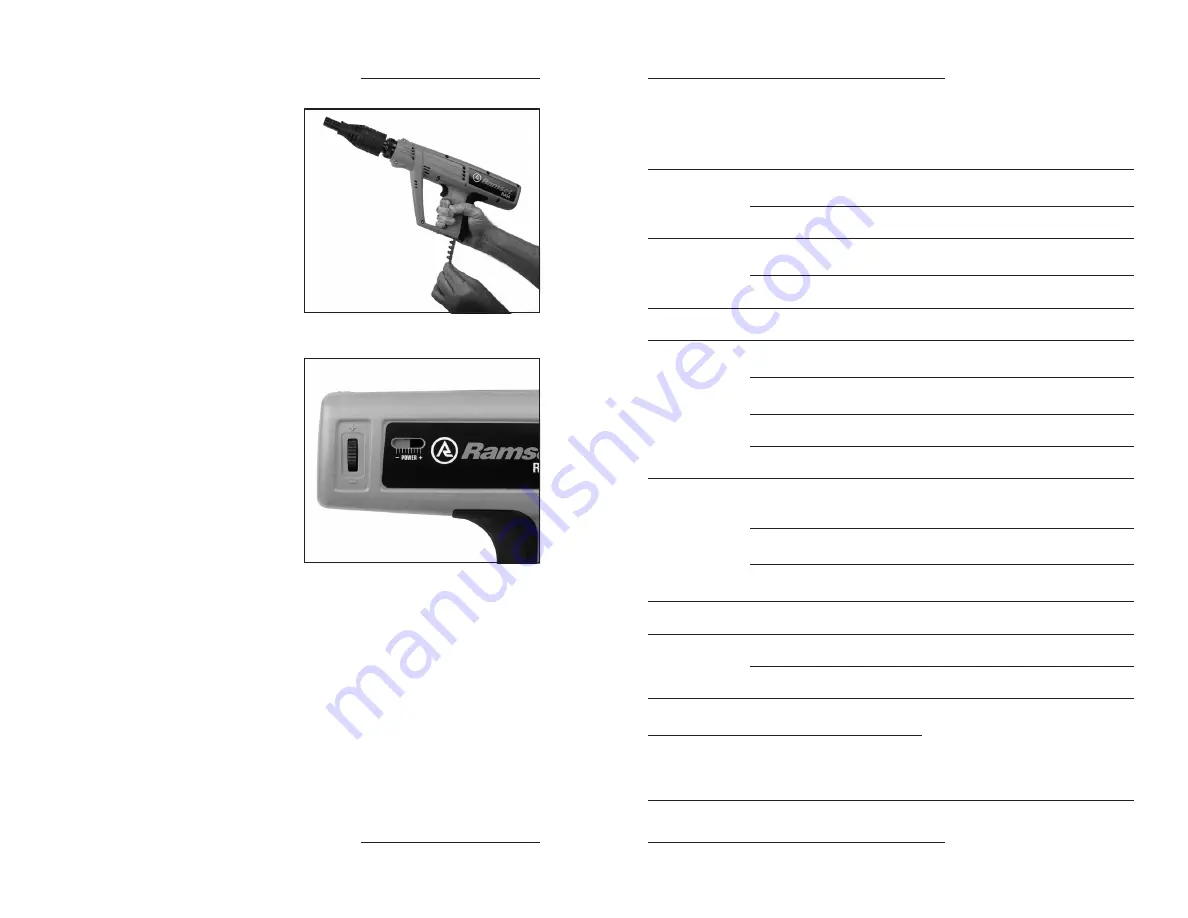

5. Adjust the power, if necessary.

Increase power by increasing power

setting. When maximum setting is

reached, move wheel back to minimum

position and insert next strength power

load.

2. INSERT THE POWER LOAD

5. ADJUST THE POWER, IF NECESSARY

Most commonly, problems are caused by over driving due to poor fastener or charge

selection. It is wise to consider these two factors as the first options in trouble shooting.

SYMPTOM

POSSIBLE PROBLEMS

SERVICE

— Fastener over

driven

— Too much power

— Use a low strength power load or use the

power adjustment feature if applicable

— Fastener too short

— Select the correct fastener

— Fastener under

driven

— Too little power

— Use a higher strength power load or use

the power adjustment feature if applicable

— Fastener too long

— Select the correct fastener

— Rough action

— Excessive carbon build up

— Disassemble, clean and lightly oil tool

— Reduction or loss

of power

— Piston not returning to position

— Check the length of the piston return spring

(Refer to page 13)

— Faulty piston return spring

— Remove piston. Replace piston return

spring

— Buildup of dirt in tool

— Clean tool parts

— Broken piston

— Replace piston

— Tool misfire

Do not remove the

tool from the work

surface for at least

30 seconds

— Failure of tool to depress

completely

— Disassemble tool and check all parts for

correct assembly after first removing the

power loads

— Cartridge strip damaged

— Remove and replace with new cartridge

strip

— Problem with tool or faulty

charge / power load

— Refer to misfire procedure on page 6

— Tool Jam

— Damage to power load chamber

— Refer to misfire procedure on page 6

— Cartridge strip

does not index

in tool

— Cartridge strip damaged

— Refer to misfire procedure on page 6

— Strip index mechanism damaged — Refer to misfire procedure on page 6

— Cartridge strip

melts

— Tool overheated – fastening rate

too high

— Allow tool to cool. Disassemble tool to

increase rate of cooling

— Cartridge falls out

of the strip

— “Hot” tool compressed for too

long

— Reduce fastening rate

— Compress tool for a shorter period of time