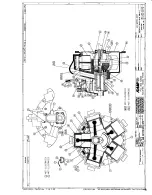

ASSEMBLY OF WHEEL DRIVE

Refer to Parts Illustration

STEP 1

Press new bearing cups (7 & 10) in each side of the hub (9). It is recommended that bearing cups (7 &

10) and cones (6 & 12) be replaced in sets.

STEP 2

Assemble bearing cone (6) into cup (7) at seal end of hub (9) and press a new seal (5) into hub (9).

Install boot seal (4) on hub (9) if unit is so equipped.

STEP 3

Position spindle (3) upright on bench. Lubricate lips of seal (4) and (5) and lower hub (9) onto spindle

(3). Hub (9) should be centered as it is lowered over spindle (3) to prevent seal damage.

STEP 4

Assemble bearing cone (11) over spindle (3). Press bearing cone (11) over spindle bearing journal

using press and cylindrical bearing cone driver 598F. Pressure bearing cone (11) down until rollers just

touch cup (10). Take care to avoid pressuring cone (11) too far. Note: If a press is not available, place

tool 598F over splined end of spindle (3) on the edge of bearing cone (11) and drive into place with

hammer or mallet. If this method is used, care must be taken to avoid damage to bearing cone and

spindle.

STEP 5

Install thrust washer (12) and bearing nut (14).

DO NOT install lock washer (13) at this time.

STEP 6

Place spindle drive tool, 598F, over spindle (3) and bolt or pin to hub (9).

STEP 7

Check initial rolling torque by installing a lb.-in. torque wrench (arm or dial type) on center nut of spindle

drive tool and turning hub (9) slowly and steadily with the torque wrench. Note mean torque. An initial

bearing torque of greater than 52-lb. –in. with boot seal installed or 48 lb. –in. without boot seal means

that the cone (11) was pressed on too tightly in step 4. In this case, back off bearing cone (11) by

pressing spindle (3) out of cone (11) until initial preload is relieved. See step 11 of disassembly

procedure.

STEP 8

Torque bearing nut (14) with bearing nut wrench 593RR until a bearing rolling torque of 44 – 52 lb. –

in., with a boot seal installed, or 40 – 48 lb. –in., without a boot seal, is reached. This may require

several trials of pressing the cone (11) by torquing the nut (14) and then checking the rolling torque.

Rotate hub (9) by hand as nut is being tightened in order to seat bearings. Note: Up to 250 lb. –ft. of

torque may have to be applied to bearing nut (14) in order to press cone (11) into position.

STEP 9

Remove bearing nut (14) and install lock washer (13). Replace bearing nut (14).

STEP 10

Re-torque bearing nut (14) to 65-75lb. – ft. (88 – 100 Nm).

Summary of Contents for K5UR120ML-AM1G Series

Page 1: ...MODEL K5UR120ML XX AM1G UTILITY AND MANLIFTER AIR WINCH ...

Page 2: ......

Page 3: ......

Page 4: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ...above ...

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ...Brake Mount Assembly ...

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 54: ...K5W 507 PD5 H505A ...

Page 55: ...KD5 A501 Model No AG78301 402790 1M ...

Page 56: ......

Page 57: ...RAM P N AH04414R Double Reduction Wheel Drive SERVICE MANUAL ...

Page 64: ......

Page 68: ......

Page 69: ...Component Data Sheets ...

Page 70: ......

Page 71: ...RAM P N AG35139 Air Cylinder ...

Page 72: ......

Page 73: ...RAM P N AG35139 A Air Cylinder ...

Page 74: ......

Page 75: ...RAM P N LB80045R 1 1 2 LUBRICATOR ...

Page 76: ......

Page 78: ......

Page 79: ...RAM P N LB80040R 1 1 2 FILTER ...

Page 81: ......

Page 82: ......

Page 83: ...RAM P N LB80050 REGULATOR ...

Page 86: ......

Page 87: ...RAM P N AG70252 ...

Page 88: ......

Page 89: ......

Page 90: ...K5UR120ML Air Winch RAM WINCH HOIST 12 05 K5UR120ML Air Winch RAM WINCH HOIST 11 06 ...