Page 5 of 22

IN052 Rev. K 0613

Mid-Range Flow Rate Test:

1.

Attach garden hose to the drain connection on the base of the Well Pressure Tank.

2.

Open the drain valve and run water for 15 minutes.

3.

After 15 minutes, check the pressure gauge on the well system. Adjust the drain valve (open or

close) as needed to maintain the required running system pressure (constant pressure on gauge)

with the well pump running continuously.

4.

Run for 5 minutes while ensuring that the pressure is not fluctuating.

5.

Run water from the hose into a five gallon bucket. Using a stop watch, time how many seconds it

takes to fill the bucket (Z sec.).

6.

Determine the GPM by dividing 60 seconds by the number of seconds it took to fill the bucket (Z

sec.). Multiply the answer by 5 gallons. This gives you the GPM.

GPM = ( 60 / Z ) x 5

7.

Repeat steps 5 and 6 and average the 2 numbers. The answer is the well pump output in gallons per

minute. It is recommended that this number be indelibly recorded in an obvious location, together

with the date of test, as it will be required when setting the AIRaider

™

EZ

95

System and may be re-

quired for future troubleshooting of the well pump system or the AIRaider

™

EZ

95

System.

Failure to remove other contaminants can reduce the effectiveness of the system and may result in system damage!

1.3. Full Water Test

A full Water Sample Analysis must be performed to determine the quality of the water that requires treat-

ment. In many water supplies, contaminants other than radon are present. The AIRaider

™

EZ

95

System

is only effective for the removal of radon and some other VOCs. The Aeration Process employed by the

AIRaider

™

EZ

95

System and other radon removal systems can worsen problems due to iron or manganese

contaminants in the water supply. For optimal removal of radon or other VOCs, other contaminants such as

sediment, iron, or manganese must be removed before the water supply enters the AIRaider

™

EZ

95

.

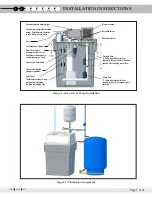

1.4. Unpacking and Locating System Components

1.4.1. Unpack All System Components

Remove all packing material and discard appropriately away from the work area.

1.4.2. Locate All Components

Check to ensure all components are intact and included in shipment.

Included Component List (may vary with order)

•

Tank Assembly

•

Pump (Installed Inside Tank Assembly)

•

Diffuser Assembly (Installed Inside Tank Assembly)

•

Bypass Valve (Sold Separately)

•

Bladder Tank (Minimum 5 gallon. Sold Separately)

•

Manual

Household water use must be discontinued during the following flow rate test.

PRE-INSTALLATION

1