INSTALLATION INSTRUCTIONS

CONDENSING BOILOES WITH STORAGE - TG05A095.A0306

15

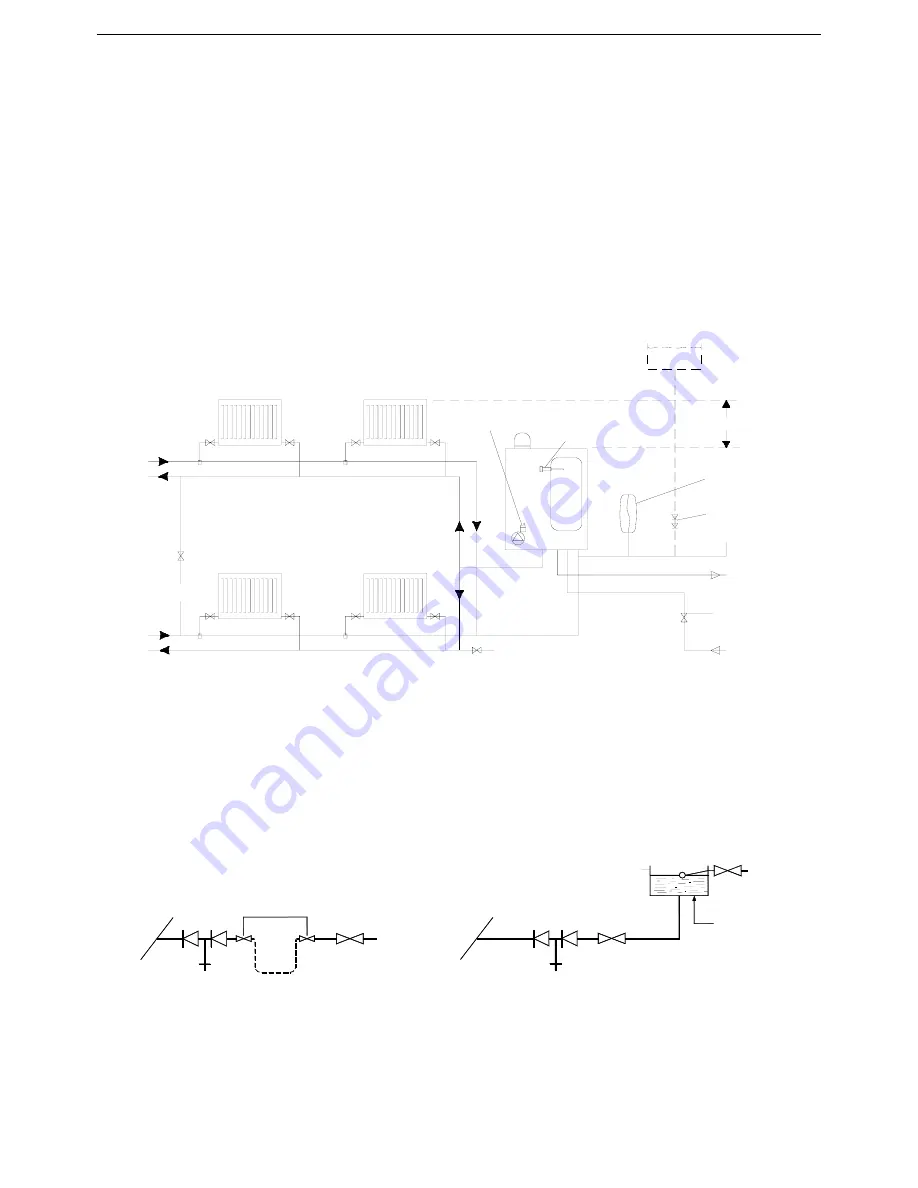

3.5 Central heating circuit

The boiler is designed for use in a sealed central heating system in accordance with the requirements of BS 5449 and BS 6798.

The system should be designed to operate with flow temperatures of up to 82°C. When designing the system, the pump head,

expansion vessel size, mean radiator temperature, etc. must all be taken into account. Refer to the pump performance table for

guidelines.

System volume -The expansion vessel incorporated into the boiler is suitable for a sealed heating system

The boiler is supplied with the following components built in:-

Pressure relief valve

-complying with BS 6759 and set to operate at 3 bars. The outlet connection of the boiler safety valve

must terminate to atmosphere in accordance with current regulations. The manufacturer will not be held responsible for

flooding caused by the operation of the safety valve in the case of system overpressure..

Pressure gauge

-To indicates the system pressure to be maintained.

Expansion vessel

. Conforming to BS 4814 with a capacity of 10 litres.

By-pass

-The boiler incorporates a by-pass, however where all radiators are fitted with thermostatic radiator valves it is

recommended an automatic system by-pass is fitted.

Additional expansion

vessel (if required)

Double check valve assy

Temperature/pressure

relief valve

Boiler

Automatic air vent

Heating flow

Heating return

System

drain tap

Note:

A drain tap should be installed at the lowest point of the

heating circuit and beneath the appliance

Note

: If required, an automatic

by-pass is preferred

Radiator

valve

Filling point

DHW outlet

Pressure reducing

valve (supplied)

Mains water

inlet

Static head of system

Make up vessel

Heating by-pass

(if required)

Lockshield valve

Filling the central heating system

- figs. 2-3

The system design pressure (cold) should be set to 1.5 bar. This pressure is equivalent to a static head of 15.4 metres of

water.

Provision should be made to replace water lost from the system. This can be by manual or automatic means. as shown in Figs.

2 and 3. The position for connecting an automatic make-up vessel is indicated in Fig. 1. A double check valve assembly must

be used. as shown in Fig. 3.

Filling of the system must be carried out in a manner approved by the local Water Undertaking. Where allowed the system may

be filled via a temporary connection as shown in Fig. 2. After filling, always disconnect the flexible hose of the filling loop.

All fittings used in the system must be able to withstand pressures up to 3 bar.

Drain taps (to BS 2879) must be used to allow the system to be completely drained.

Double

check valve

assembly

Test

cock

Feed cistern to be

located above highest

point in the system

Overflow

Heating

circuit

return

Test

cock

Double

check valve

assembly

Stop

valve

Mains water

supply

Mains

water

supply

Stop

valve

Filling loop

temporarily

connected

Hose

unions

Heating

circuit

return

In

order to prevent scaling or deposits in the primary heat exchanger, the mains supply water to the heating circuit

must be treated according to the requirements of standard.

This treatment is indispensable in the case where the circuit is frequently topped-up or when the system is often either partially

or fully drained.

Fig. 1

Fig. 2

Fig. 3

Summary of Contents for RKA 25

Page 2: ......