Dynalyzer – High Voltage Unit

OPERATION MANUAL

28

Maintenance

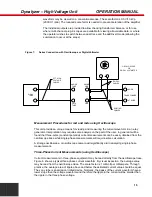

System Pressure

The High Voltage Unit is insulated with pressurized Sulfur Hexafluoride Gas (SF

6

). Every effort has

been made to ensure a leak-tight system. The unit is pressurized to 30 psig when shipped and

contains a relief valve set at 30 psi. The unit is filled at sea level. Transportation in unpressurized

aircraft, or in cargo holds with reduced pressure, will result in an increase in the differential

pressure as compared to sea level (14.7 psi).

Effects of altitude variation such that the sum of internal pressure plus atmospheric pressure is

greater than 22 psi will result in satisfactory operation at voltages up to 150 kVp. If there is a loss in

pressure due to this effect, the unit should be recharged to 30 psi. Any leak due to other causes

should be identified. Recharging may be accomplished with the contents of a lecture bottle of

Sulfur Hexafluoride, C.P. gas, available from Matheson Gas Products Company. The contents of

one lecture bottle of SF

6

(

1

/

2

pound) is adequate to completely fill the system. As long as there is

positive pressure in the High Voltage Unit, purging of the unit will not be necessary.

Failure Modes

Protective circuitry in the High Voltage Unit has been incorporated to suppress high voltage

transients that may be generated under fault conditions. The anode current transmitter, under

extreme operating conditions, can sustain damage. This would be evidenced by either saturation

of the mA output signal, or a negative offset of 100 mV.

Loss of internal pressure will result in a decrease in the insulation properties of the internal gas

(SF

6

) which could reflect itself as internal arcing between components, or to ground. This could

result in the destruction of some semi-conductor elements.