QUICK EA-A10 OPERATION MANUAL

Page 17

After edit parameter in parameter setting display, in

“

flow edit display

”

input flow name, appropriate nozzle

size, select flow technology curve is “desolder”

、

or “solder”. And then click “parameter save”

、

“save curve”

,

can save current parameter and flow curve.

In parameter setting display, can set parameter, setting range refer to 5.1.

T0: only satisfy “TIR

≥

T0”, hot air system can start working. No special purpose, please set Tir

>

T0.

Can also click “flow select” in “edit flow display”, call saved parameter and modify it. heat dissipation air

quantity : 35

~

100.

Note: parameter setting please refer to technology require.

11.4

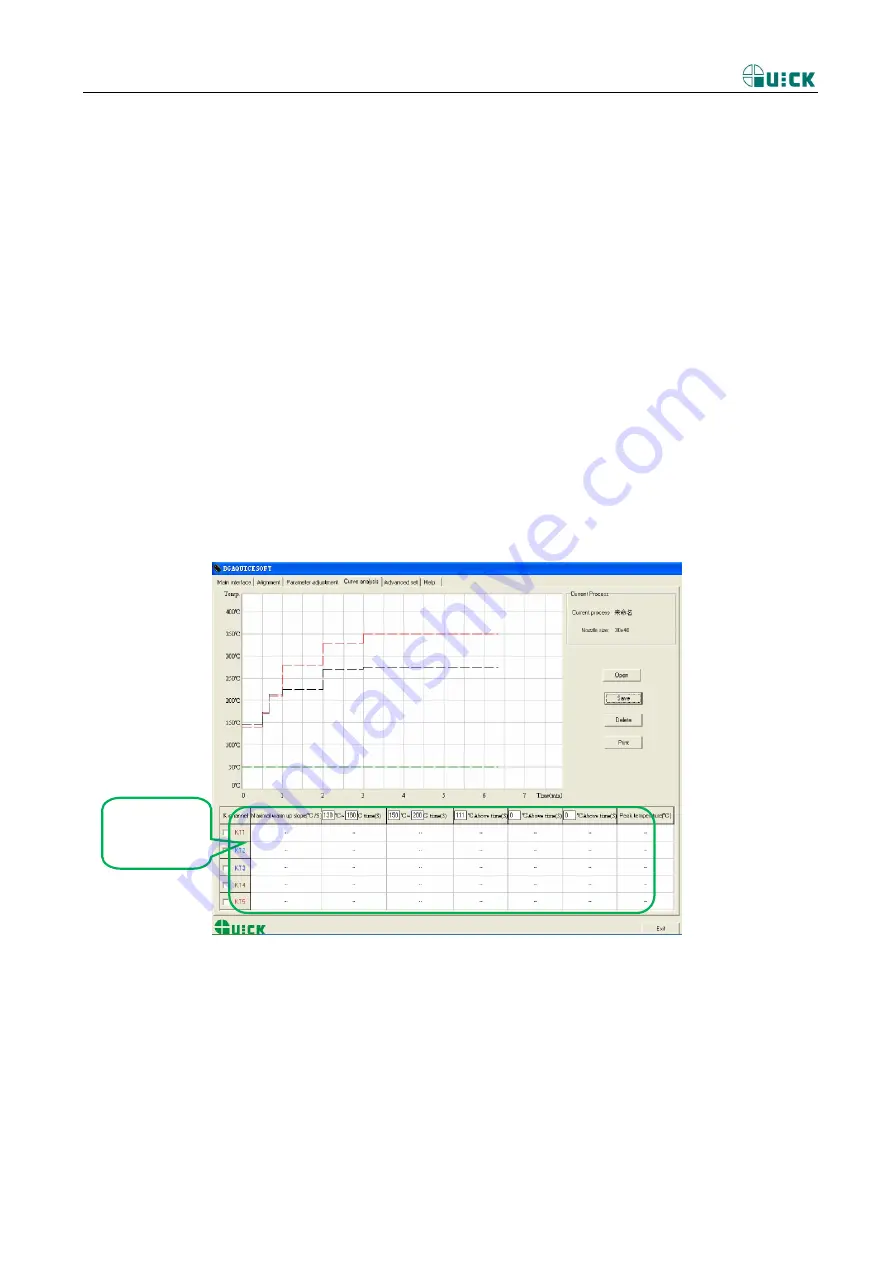

curve analysis display

1.

Curve analysis display: this display can analysis KT1

-

KT5 flow curve, know peak temperature of this flow,

temperature rise slope, temperature change of every heat process and time, thus judge if correspond

technology flow.

2.

In curve analysis interface, can save or delete current curve, or call saved curve analysis, and also print

current curve file.

3.

After open flow file , flow curve interface auto display flow curve; if flow file contain external K type

temperature test data, then display temperature arise time, maximum temperature rise slope, peak

temperature.

11.3

advanced setting interface

Advanced setting: in this interface, we can set operation limits of authority, communicate video etc. and also can

set T0, temperature curve colour and wire wide, and can select china and English.

Data analysis

interface