LTE Standard Module Series

EC200T Series Hardware Design

EC200T_Series_Hardware_Design 34 / 90

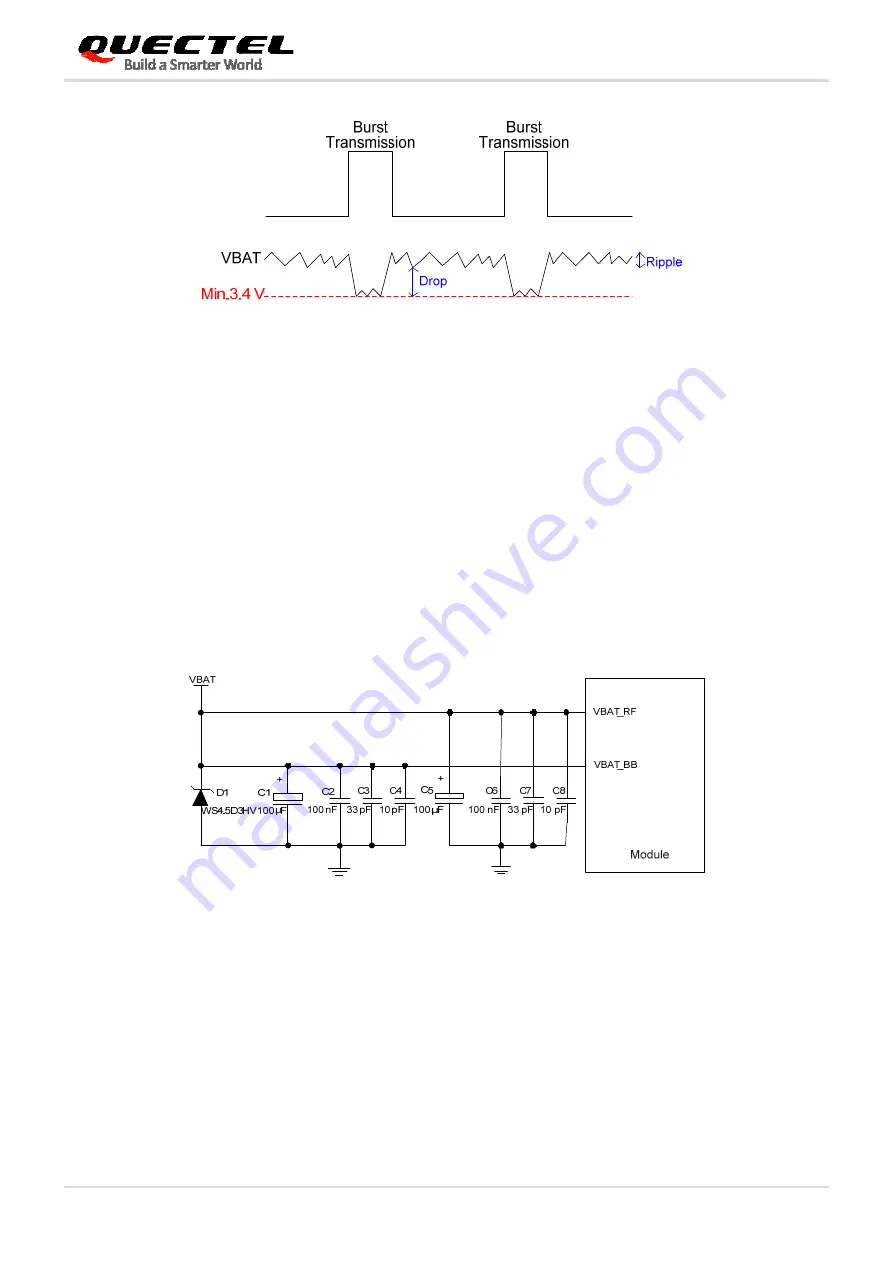

Figure 6: Power Supply Limits during Burst Transmission

To decrease voltage drop, a bypass capacitor of about 100 µF with low ESR (ESR = 0.7

Ω

) should be

used, and a multi-layer ceramic chip (MLCC) capacitor array should also be reserved due to its ultra-low

ESR. It is recommended to use three ceramic capacitors (100 nF, 33 pF, 10 pF) for composing the MLCC

array, and place these capacitors close to the VBAT_BB and VBAT_RF pins. The main power supply from

an external application has to be a single voltage source and can be expanded to two sub paths with star

structure. The width of VBAT_BB trace should be no less than 1mm; and the width of VBAT_RF trace

should be no less than 2 mm. In principle, the longer the VBAT trace is, the wider it will be.

In addition, in order to ensure the stability of power source, it is suggested that a TVS diode of which

reverse stand-off voltage is 4.7 V and peak pulse power is up to 2550 W should be used. The following

figure shows the star structure of the power supply.

Figure 7: Star Structure of Power Supply

3.6.3. Reference Design for Power Supply

Power design for the module is very important, as the performance of the module largely depends on the

power source. The power supply should be able to provide sufficient current up to 2.0 A at least to the

module. If the voltage drop between the input and output is not too high, it is suggested that an LDO

should be used to supply power for the module. If there is a big voltage difference between the input

source and the desired output (VBAT), a buck converter is preferred to be used as the power supply.