6-4

Preventative Maintenance

500300 Rev. U

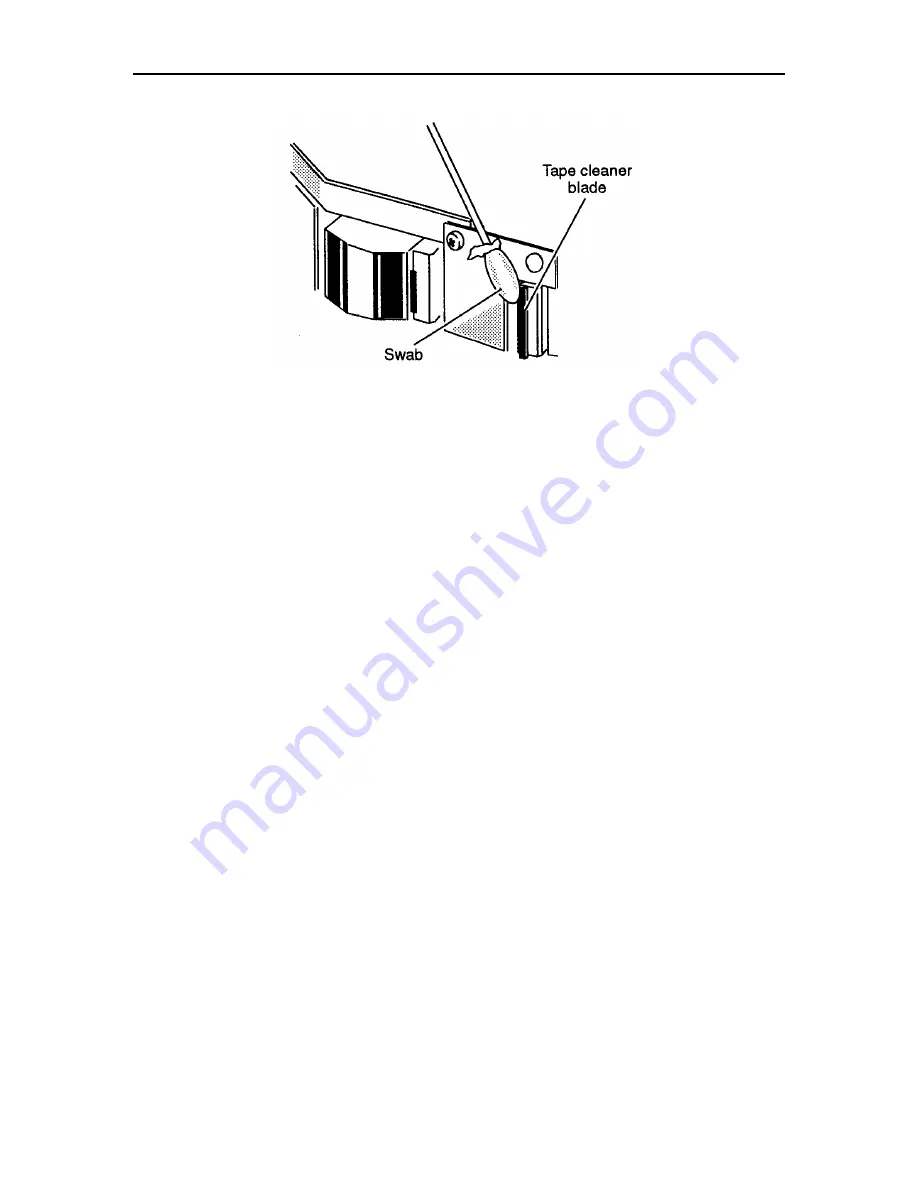

Figure 6-4 Cleaning the Tape Cleaner

4.

Run the Write/Read test described in Section 4.5.8 to verify data reliability. If

the tape drive does not pass this test after cleaning the head and tape path,

call Qualstar Customer Service for assistance.

5.

Reset the Head Clean odometer as described in Section 4-2.

TexPads

®

are individually sealed pads pre-moistened with 91% isopropyl alcohol and

are ideal for head and tape path cleaning. You can order them from Qualstar, or

directly from The Texwipe Company by calling (800) 284-5577.

6.4

Using 1-mil Tape

1-mil tape was originally designed for low-speed data logging applications. Due to

their thinner Mylar substrate, they do not meet the ANSI specifications for

thickness; however, 1-mil tape is electrically and magnetically equivalent to the

ANSI standard 1.5-mil tape.

Because of the thinner material, 1-mil tape conforms differently to the read/write

heads. As a result, the critical read/write surface of the head wears at an increased

rate and forms a profile that is different from that made by 1.5-mil tape. The

thinner tape is also more susceptible to breakage and deformation.

All Qualstar reel-to-reel tape drives will handle 1-mil tapes without deforming or

breaking them. This includes high-speed rewind as well as autoloading, in those

drives that support those features. Qualstar supports the use of 1-mil tape within

the context of the following guidelines:

1.

For the reasons previously explained, you can expect reduced head life

expectancy when using 1-mil tapes.

2.

Standard 1.5-mil tape cannot conform to the head wear pattern caused by the

frequent use of 1-mil tape, resulting in a greater distance between the tape and

the head gaps and a consequent reduction in signal strength. This can lead to