6-2

Preventative Maintenance

500300 Rev. U

workbenches will accumulate dust on the reel flanges that will eventually work

its way into the tape path. Tape which has been partially unwound onto the

floor or which has picked up fingerprints will transfer the dust and oil from the

fingerprints to the tape cleaner and guides, necessitating more frequent

cleaning.

•

Amount of tape that has passed through the tape path -

Tape drives that

run many reels of tape through them each day will require more frequent

cleaning than tape drives that are used only a few minutes a day. Your tape

drive features a head cleaning odometer that records how much tape has passed

the heads. When a predetermined value is reached, the display will read TIME2

CLEAN HEAD, reminding you to clean the tape path. The reminder will appear

each time the tape is unloaded until you reset the odometer.

NOTE

The

TIME2 CLEAN HEAD

reminder should be considered an absolute maximum and assumes

that you operate your tape drive in a clean office environment and that the tapes are handled

properly. If you operate your tape drive in a dusty environment or use dirty, old, or mishandled

tapes, you must clean the tape path more often, and the interval at which the reminder appears

should be changed accordingly. Refer to Section 4.3.2 for instructions on changing the head

clean message interval.

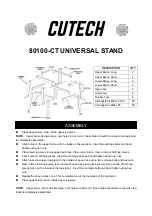

6.3

Tape Path Cleaning Procedure

Dirt on the read/write head shows up as dark brown or black smudges on the face of

the head and is often difficult to see. Use a strong light and a small inspection

mirror to see the head more clearly. When cleaning the head and tape path, use only

91% isopropyl alcohol and nonabrasive applicators such as TexPads

®

. Using abrasive

materials, detergents, or general purpose cleaning solutions can cause permanent

damage to the head surface and roller bearings. See Figure 6-1 for the location of the

components that must be cleaned.

1.

Clean the entire surface of the head, including the erase head as shown in

Figure 6-2 Rub firmly until all deposits are removed.

2.

Clean the surface of all rollers and guides as shown in Figure 6-3. Clean the

areas between the roller surfaces and their flanges. Be especially alert to

deposits under the caps on the reference guides and make sure these areas are

clean.